Tomato Sauce Processing and Filling line

This production line is meticulously crafted for the manufacturing and packaging of tomato sauce, ketchup, pepper sauce, or akin products such as jam and molasses. It offers the flexibility to integrate a packaging line catering to various containers like glass, plastic, metal, carton containers, plastic barrels, or even nylon envelopes upon request. Demonstrating an impressive production capacity of 30 tons per day, the line ensures a moderate consumption of electrical energy. Furthermore, all components of the line are made from food-grade L304 stainless steel, guaranteeing hygiene and compliance with quality standards.

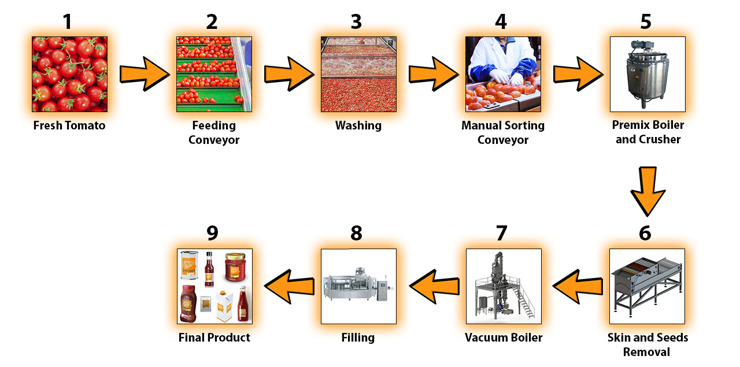

Flow Chart - Tomato Sauce Processing and Filling line

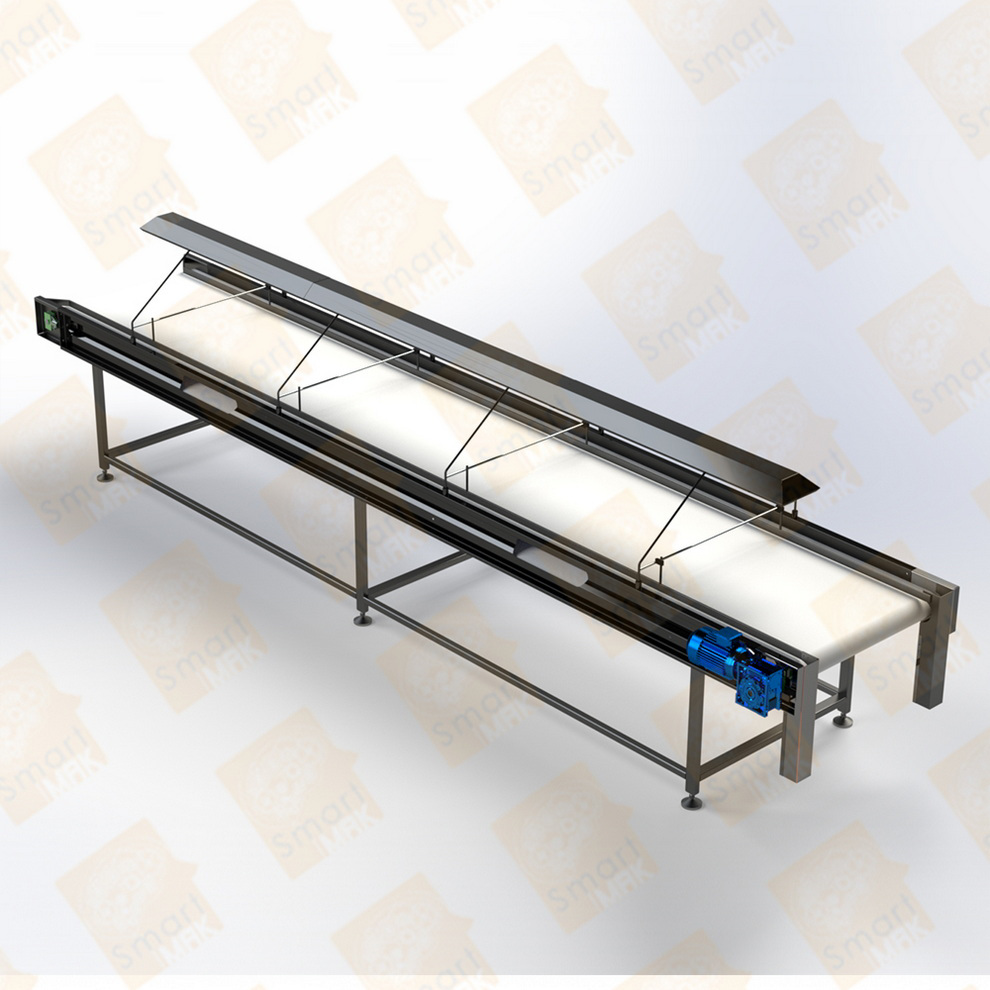

Work is done starting from the stage of receiving tomatoes and transporting them to the washing basin through a conveyor belt dedicated to receiving them, and within the basin the tomatoes are washed through air and water pressure, then the washed tomatoes pass through the control conveyor to be manually sorted, then move to the tomato crushing machine, and then the result is filtered to remove the seeds before it goes to the cooking stage, which takes place within a vacuum boiler that deflates the air to speed up the cooking process, then the sauce moves to the last stage before filling, which is the stage of pasteurization and sterilization, which is done by the tube mechanism, and then the filling process, which takes place under sterile conditions to obtain the final product.

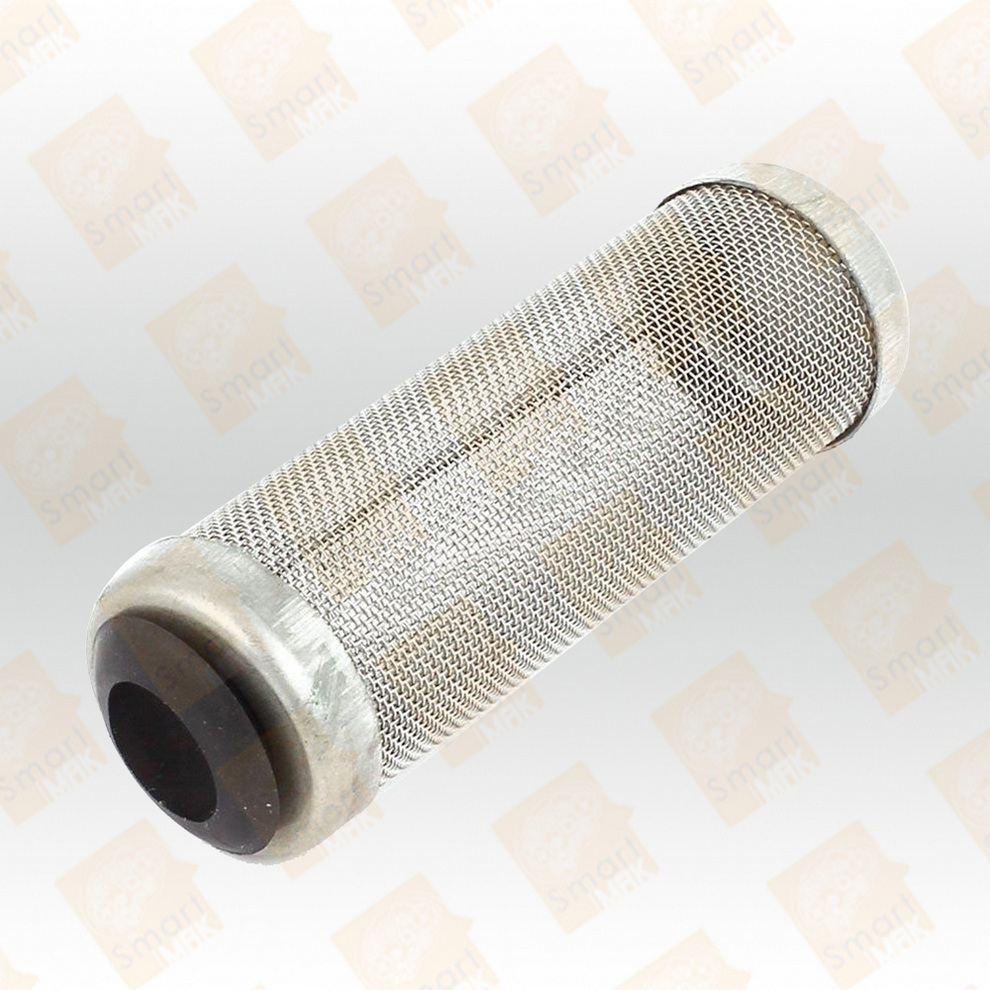

The process begins with the receipt of tomatoes, conveyed to the washing basin via a dedicated conveyor belt. Within the basin, tomatoes undergo thorough washing through a combination of air and water pressure. Subsequently, the washed tomatoes transition to the control conveyor for manual sorting. Following this, they proceed to the tomato crushing machine, and the resultant mixture undergoes filtration to removee the seeds before entering the cooking phase.

The cooking process starts within a vacuum boiler, where air is evacuated to speed up the cooking process. Following cooking, the sauce advances to the pasteurization and sterilization stage, conducted through a tubing mechanism. The final step is the filling process, executed under sterile conditions to obtain a final product with high quality and lonf shelf life.