Dates Molasses Production and Filling Line

The Date Molasses Production & Filling Line from SmartMak™ produces pure dates molasses with the concentration.

The line work starts from raw dates or dates paste to packaging in glass, plastic or metal containers of various sizes and shapes as requested.

This line is characterized by a high production capacity of up to 500 Kg per hour, and the work in it is done completely automatically and without the intervention of the labor, and it is also characterized by the presence of Clean in Place System (CIP), that guarantees washing the entire line with hot water and chlorine to clean and sterilize all parts of the line and pipes from inside.

The line's operation takes raw dates or date paste as an input and through elaborate prosedures outputs date molasses filled in glass, plastic, or metal containers of diverse sizes and shapes, as per specific requirements.

Notably, this line is of high production capacity, capable of reaching up to 500 kilograms per hour. The entire process is automated, eliminating the need for manual labor intervention. Additionally, it features a Clean in Place System (CIP) that ensures a thorough cleaning and sterilization of all components and internal pipelines using hot water and chlorine, guaranteeing hygiene and quality.

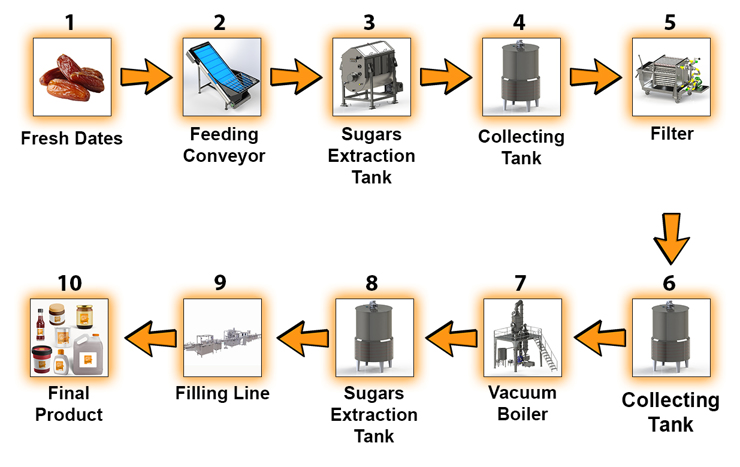

Flow Chart - Dates Molasses Processing and Filling Line

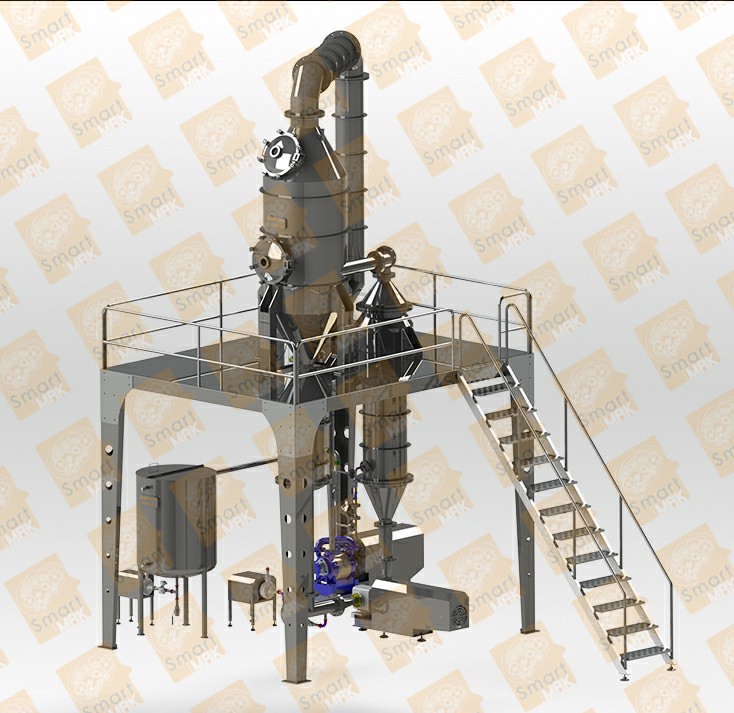

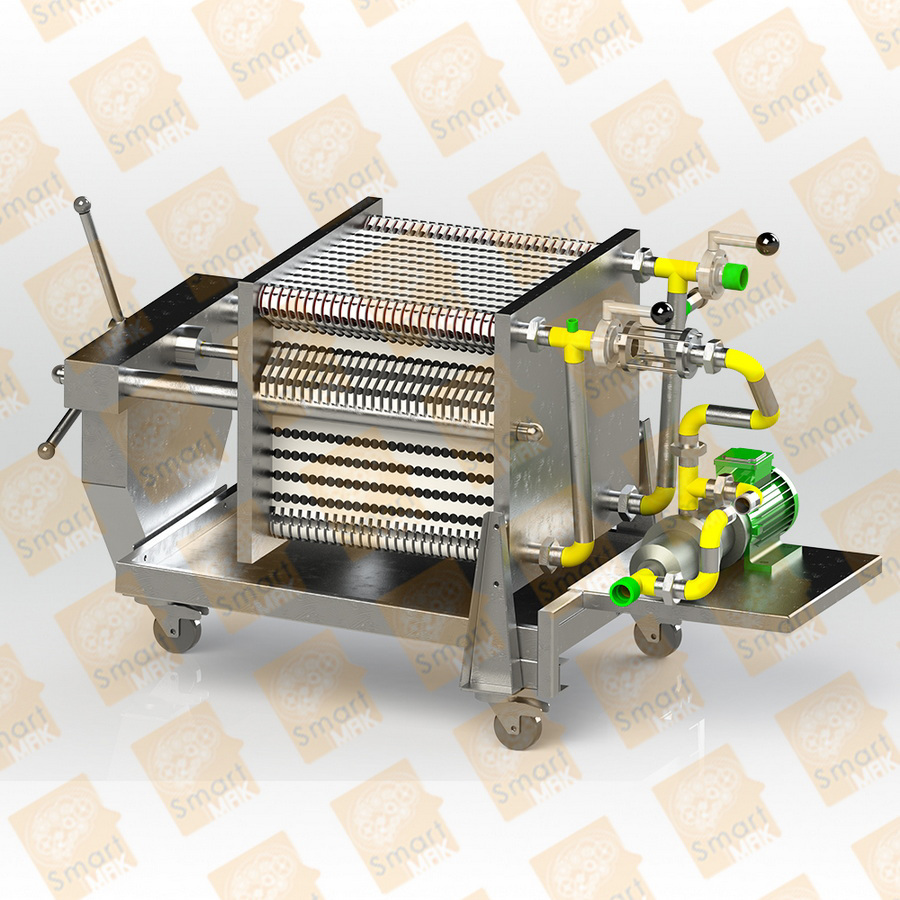

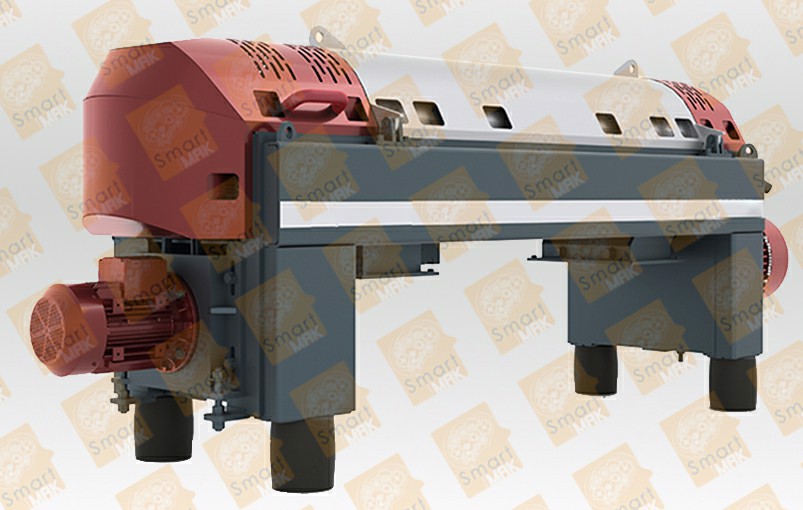

The line is designed for the production of molasses from raw dates or date paste. The process begins with the transfer of the raw material to the sugar extraction unit. Here, water is automatically added, and mixing takes place to maximize sugar extraction. The resulting liquid is then pumped into a collection tank and subsequently filtered through a decanter centrifuge and press filter to remove sediments, tissues, and cores, resulting in a clear liquid.

The clarified liquid is then moved to collection tanks in preparation for the condensation stage. Condensation occurs within vacuum condensing tanks (Vacuum Boiler) at a relatively low temperature and pressure, preserving the essential properties of the molasses. The condensed molasses is finally transferred to collection tanks, getting ready for the filling stage.

Upon request, the line can be equipped with packaging equipment to fill various container sizes. It can include a plastic gallon filling machine with a capacity ranging from 10 to 25 kg. Additionally, the line can be equipped with a small packaging line suitable for glass, plastic, or metal containers, ranging from 100 mL to 1 liter.