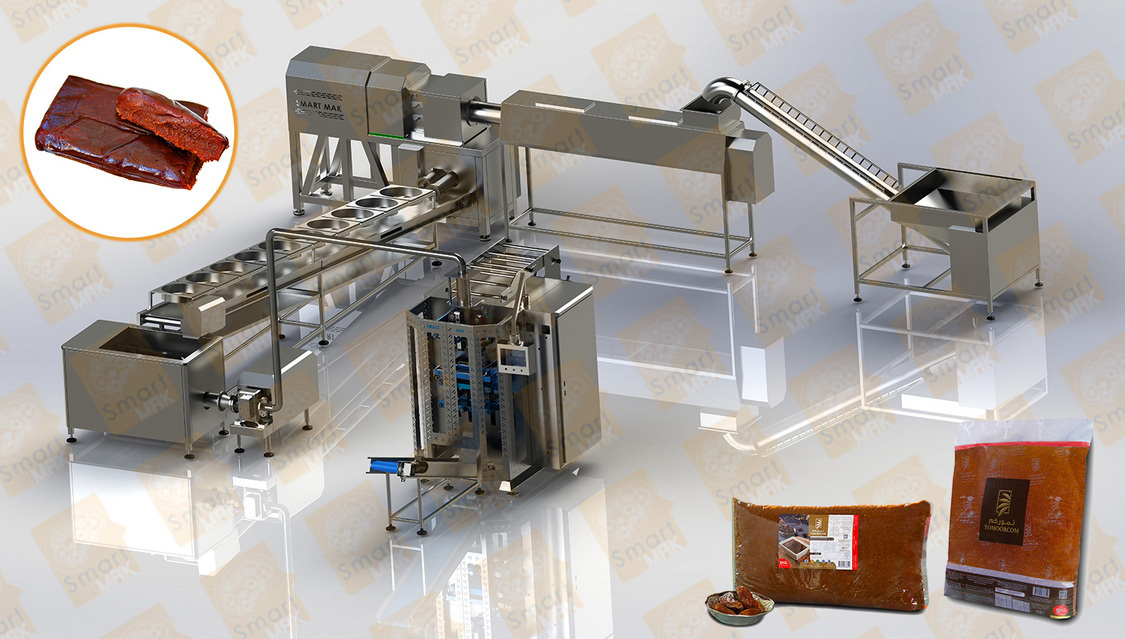

Dates Paste Production and Filling Line

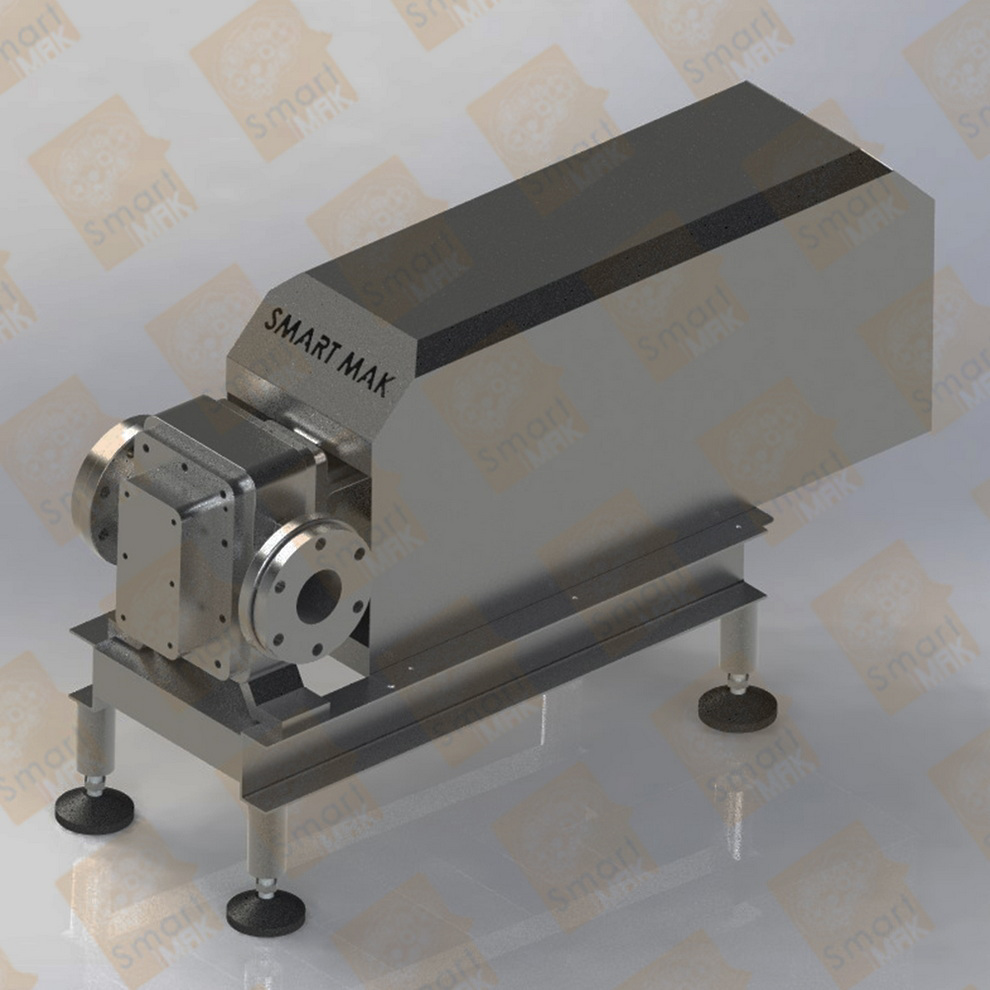

The Dates Paste Production and Filling Line from SmartMak™ is charecterized by its high quality and high production capacity, in addition to being completely automatic thanks to the seamless integration of the mechanical and electrical processes.

The line has an integrated protection system for its workers that guarantees protection from electric current surges, and ensures an automatic emergency stop when the packaging material roll ends to prevent any waste in the material.

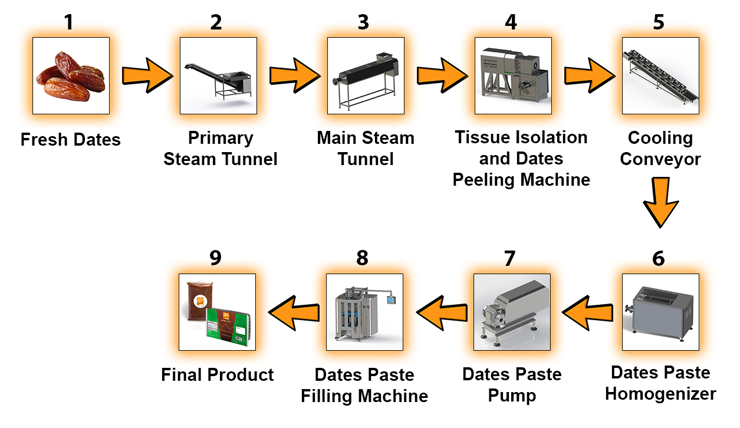

Flow Chart - Dates Paste Processing and Filling Line

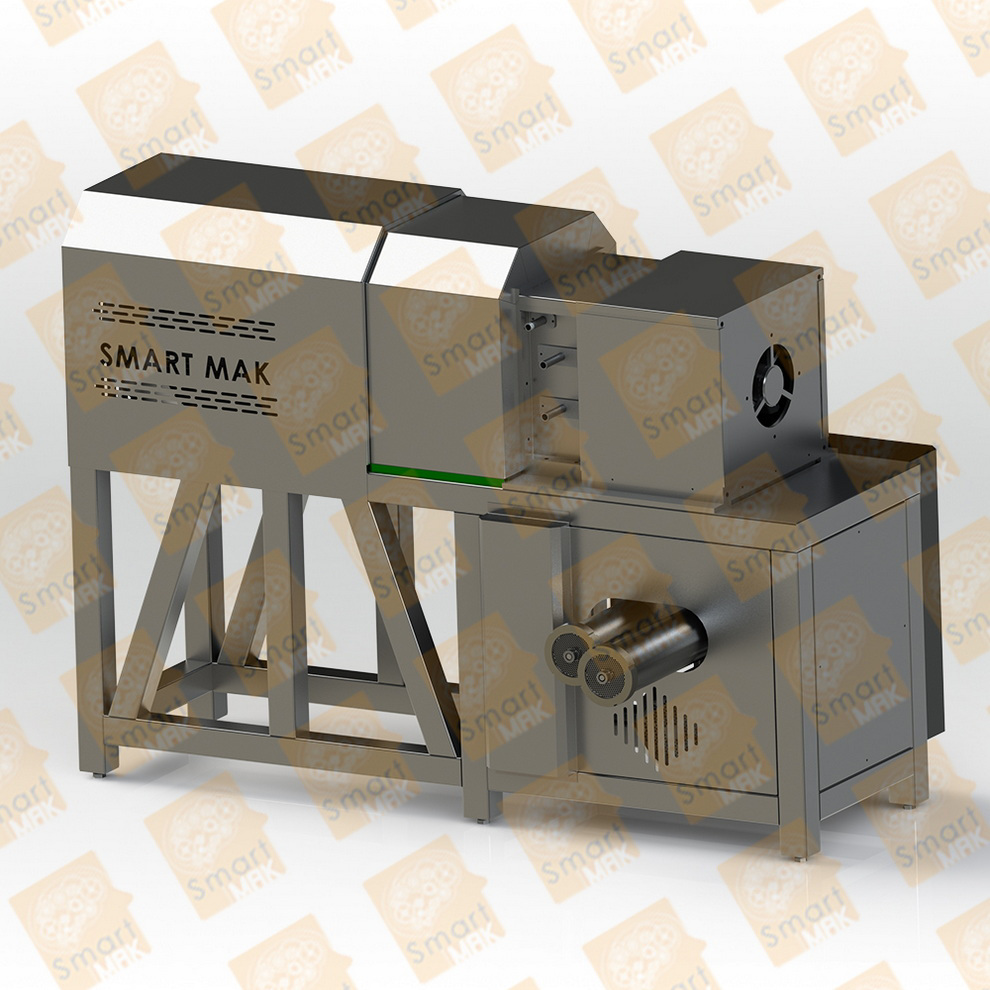

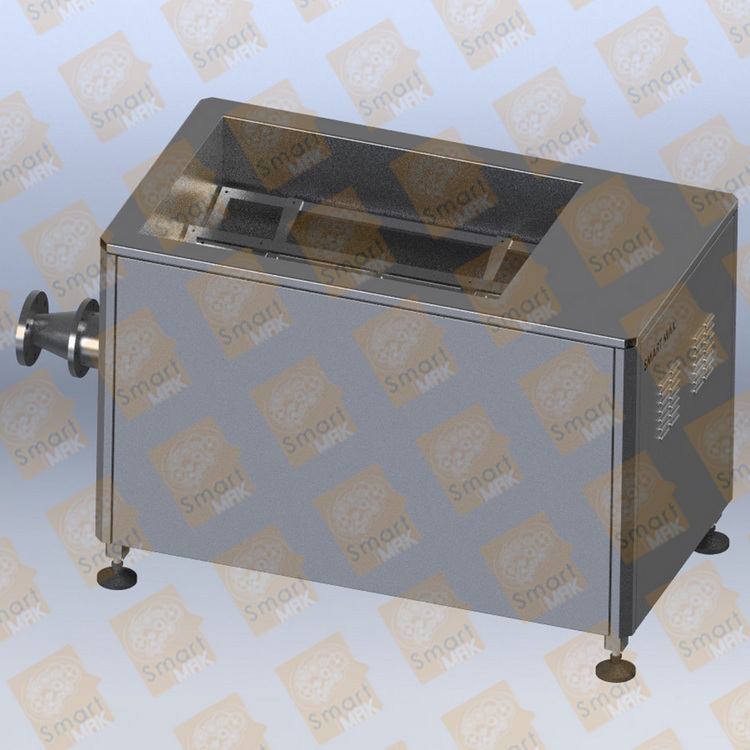

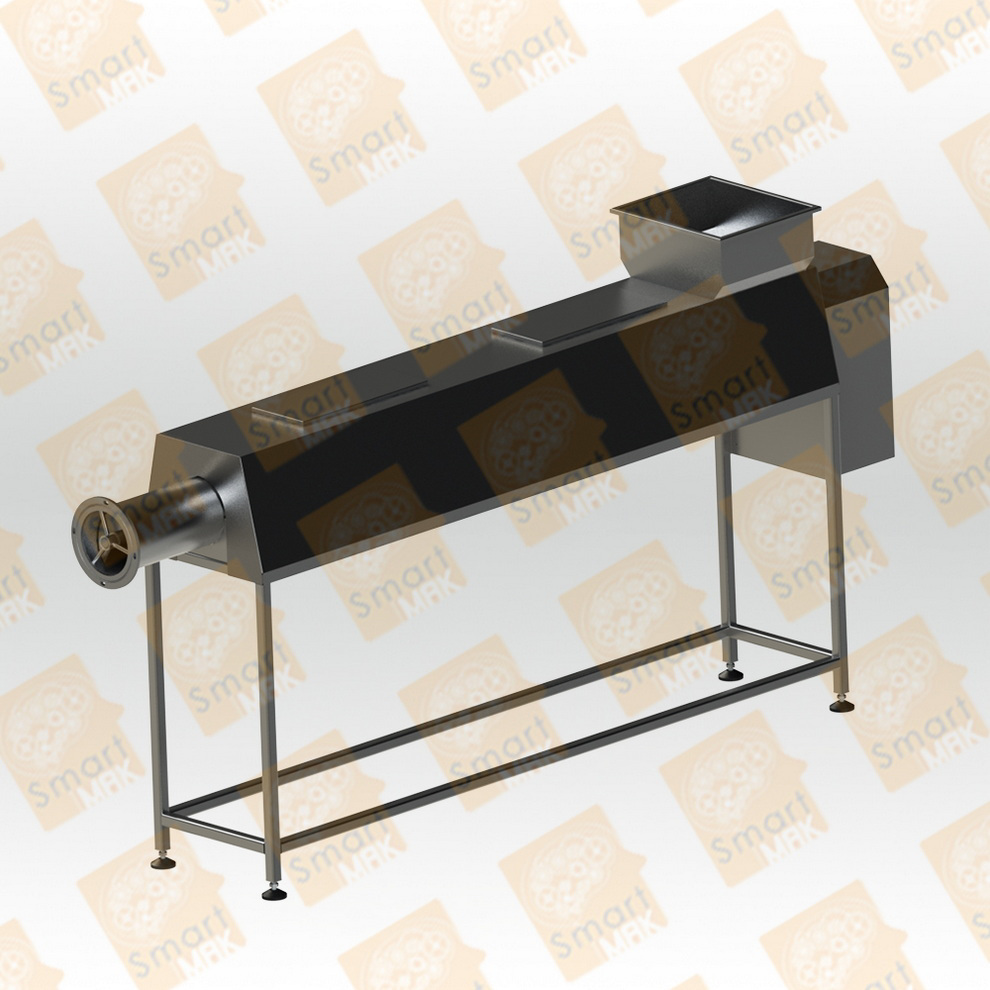

The production journey starts with the reception of raw dates, accommodating various types, whether they are dry or moist. The dates pass through the primary and main steam tunnels, guaranteeing thorough moistening and sterilization. Subsequently, the moistened dates proceed to the pitting and tissue removal unit, which efficiently extracts the date cores with minimal waste. This unit also finely chops the resulting dates.

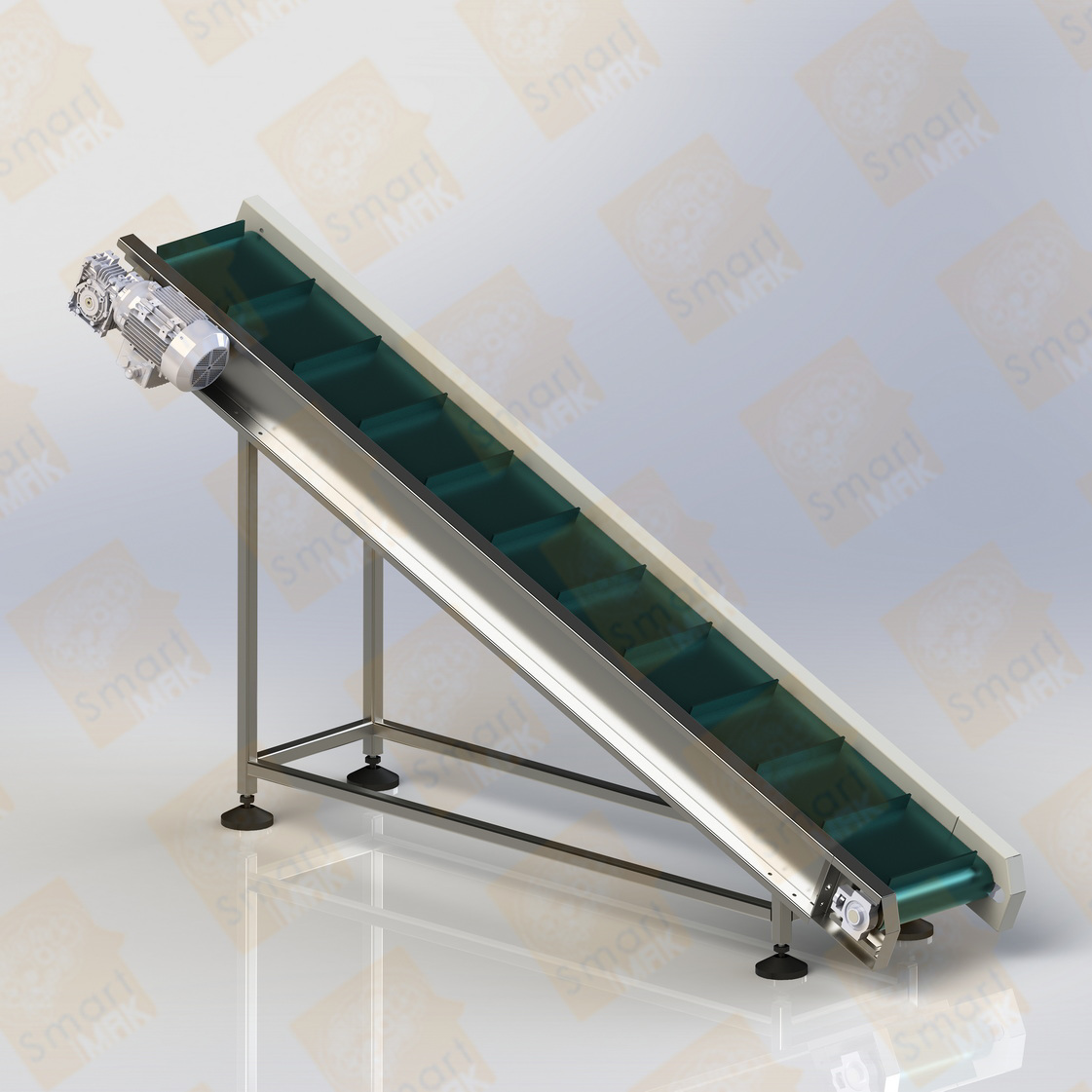

Following this, the product is gently cooled within a dedicated tunnel, preparing it for homogenization. The homogeneous paste is then conveyed through a specialized pump to the packaging machine, where it is sealed within transparent or printed thermal bags. Notably, our line employs a vacuum packing process to preserve the paste's freshness by preventing fermentation and oxidation.