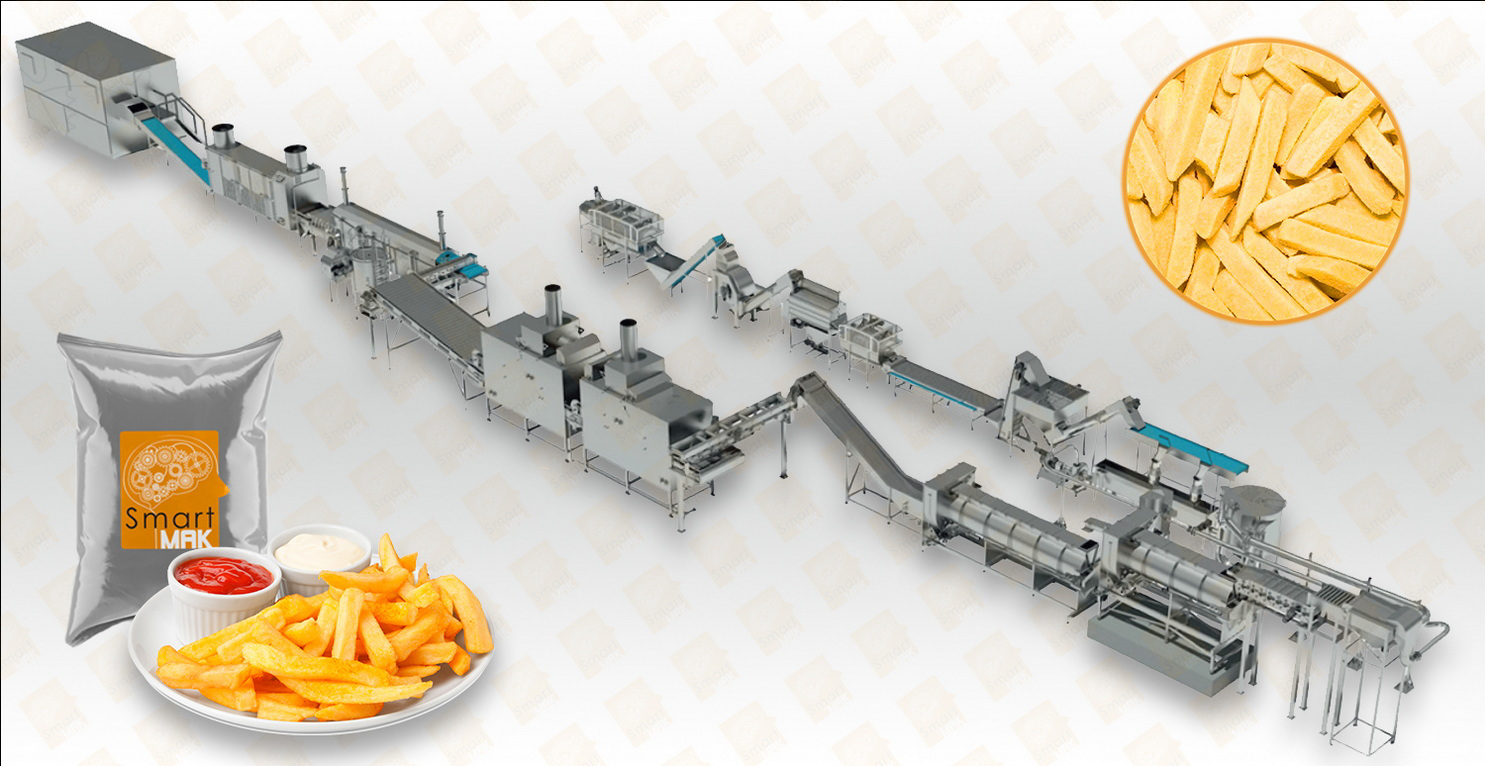

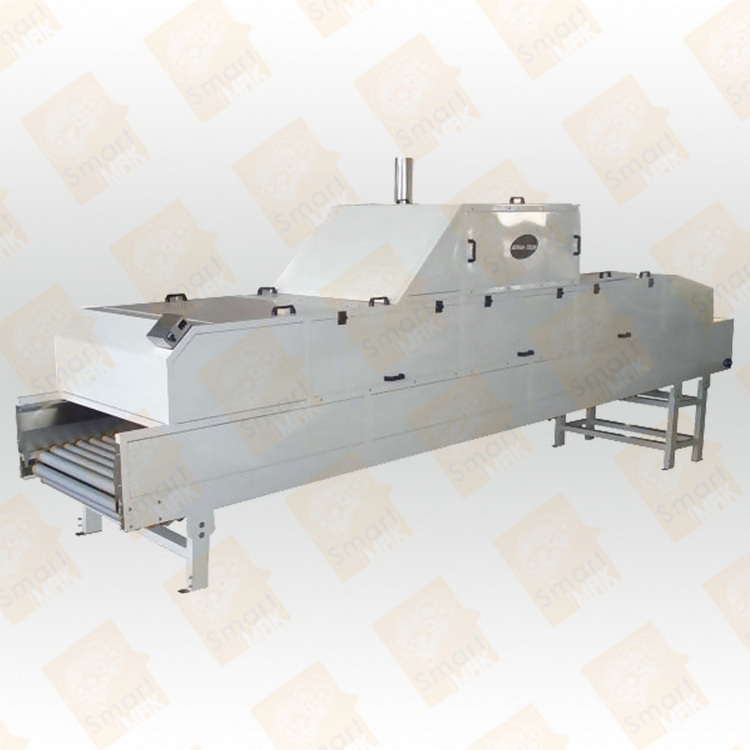

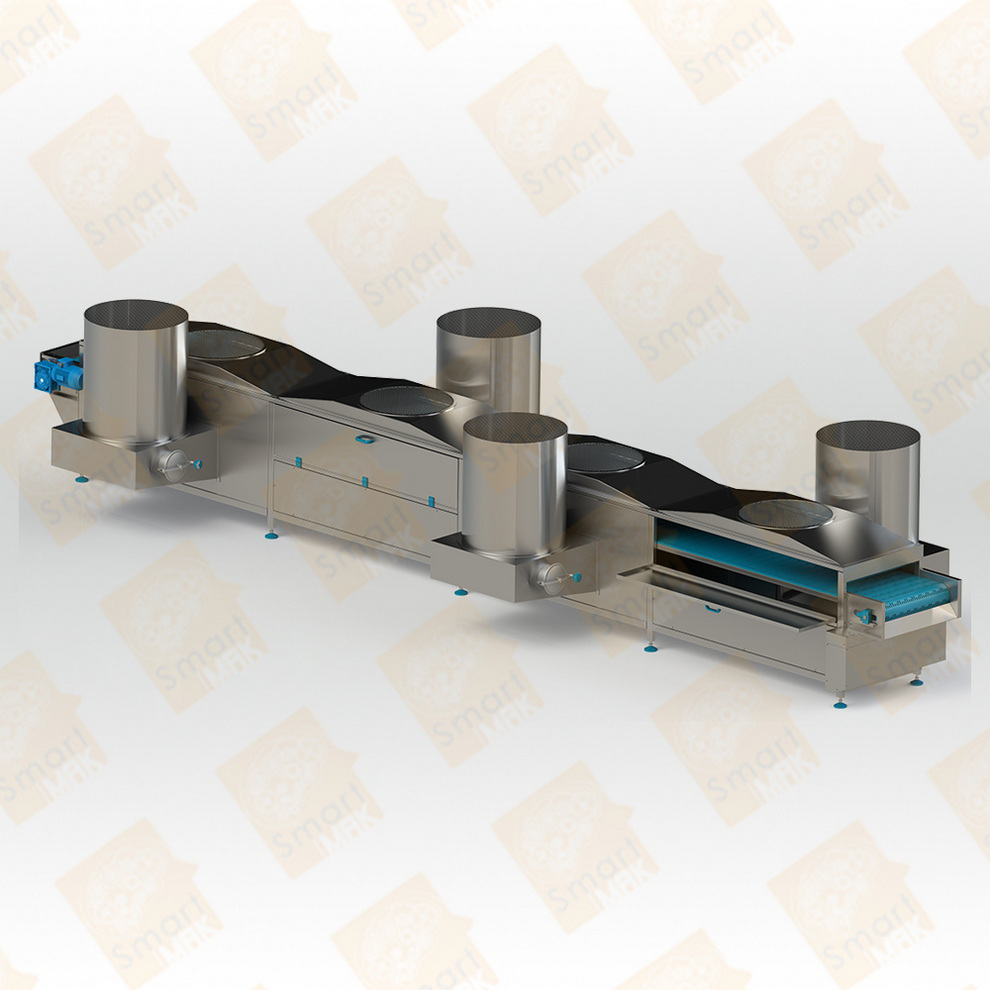

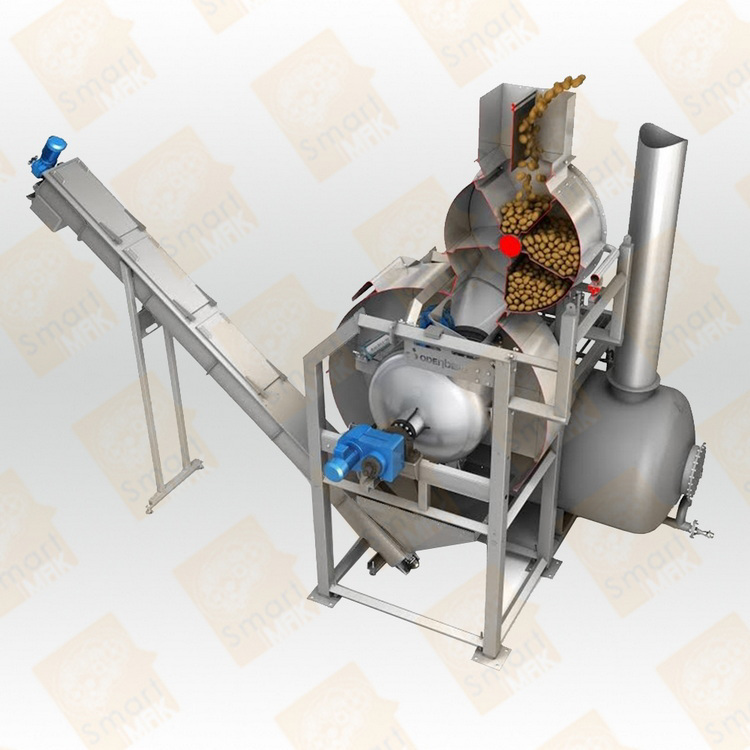

Frozen French Fries Processing and Packing Line:

The Frozen French Fries Processing and Packing Line from SmartMak™ is characterized by its high quality and high production capacity, in addition to the completely automatic production within this line without any manual intervention, and the production is carried out in accordance with international specifications, the line is CE certified.

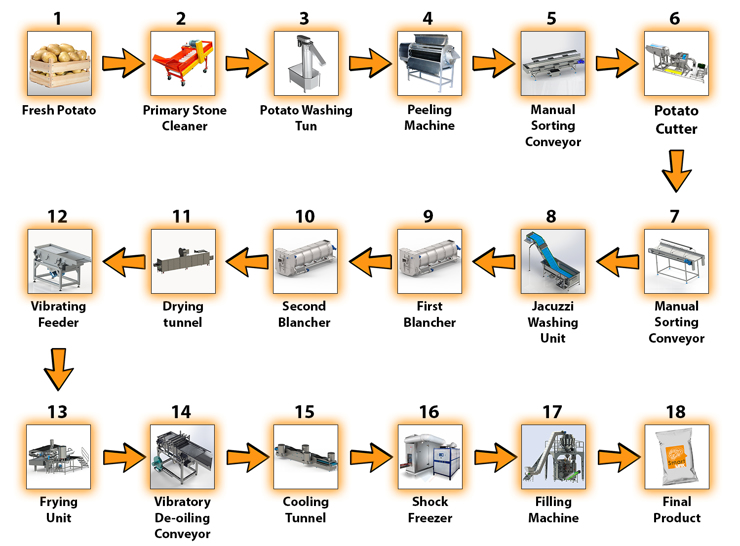

Flow Chart - Frozen French Fries Processing and Packing Line

The process starts from the stage of receiving the potatoes, passing through the stage of cleaning them from the dust and peeling them, then they are cut into fingers with adjustable dimensions as desired, then the fingers are washed and de-starched in two stages to ensure high quality, then the potatoes are dried to prepare them for the frying stage, which takes place within an efficient automatic frying unit that filters the used oil and compensates for the deficiency constantly, then the sticks pass the vibratory de-oiling unit before they go through the cooling and rapid freezing stage (Shock Freezer), reaching its packaging in the final product bags.