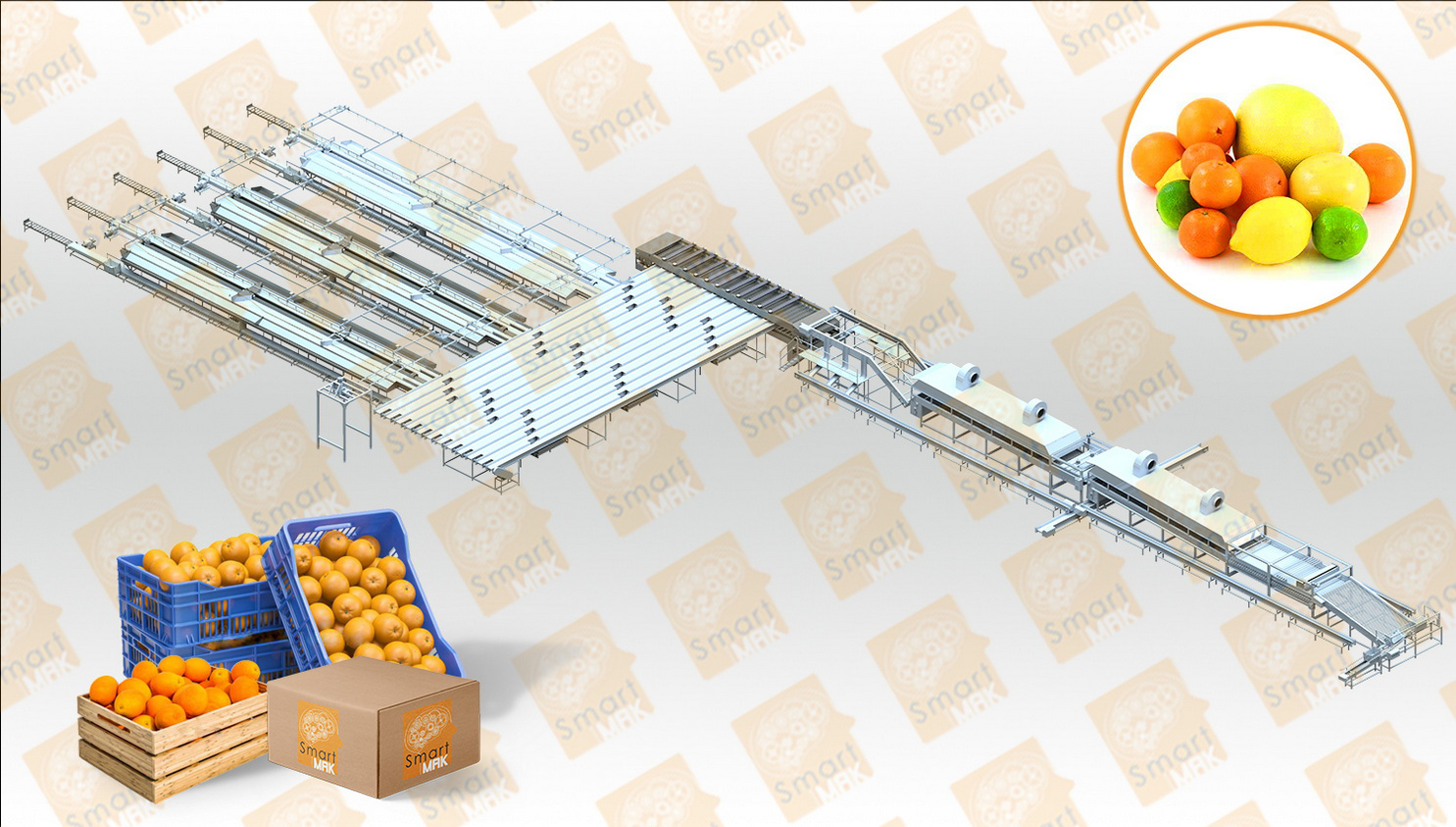

Fruits Processing Line (Washing-Waxing-Grading)

The Fruits Processing Line (Washing-Waxing-Grading) from SmartMak™ stands out for its high quality, adhering to the international standards and holding the European quality certificate CE.

This line serves as an excellent solution for cleaning and polishing various fruits, accommodating all types of citrus fruits and fruits with a solid structure like oranges. The line ensures the production of clean, polished fruits sorted by size and packaged in various shapes as per demand.

Fruits Waxing Advantages

Waxing provides several advantages to the fruits. It enhances their shine, making them more visually appealing. Additionally, the waxing process reduces water loss from the fruits, slowing down changes in shape, color, or taste. This contributes to an extended preservation period for the fruits.

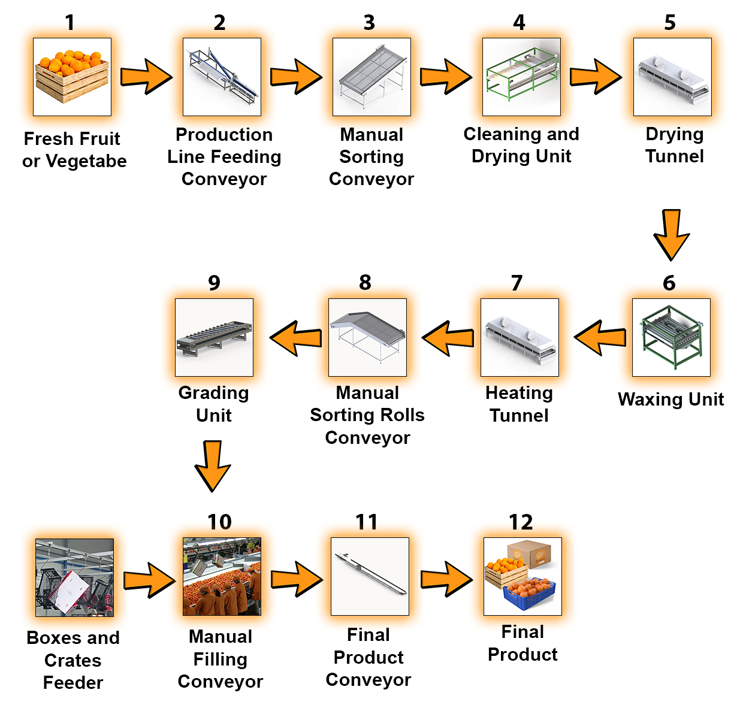

Flowchart - Fruits Processing Line (Washing-Waxing-Grading)

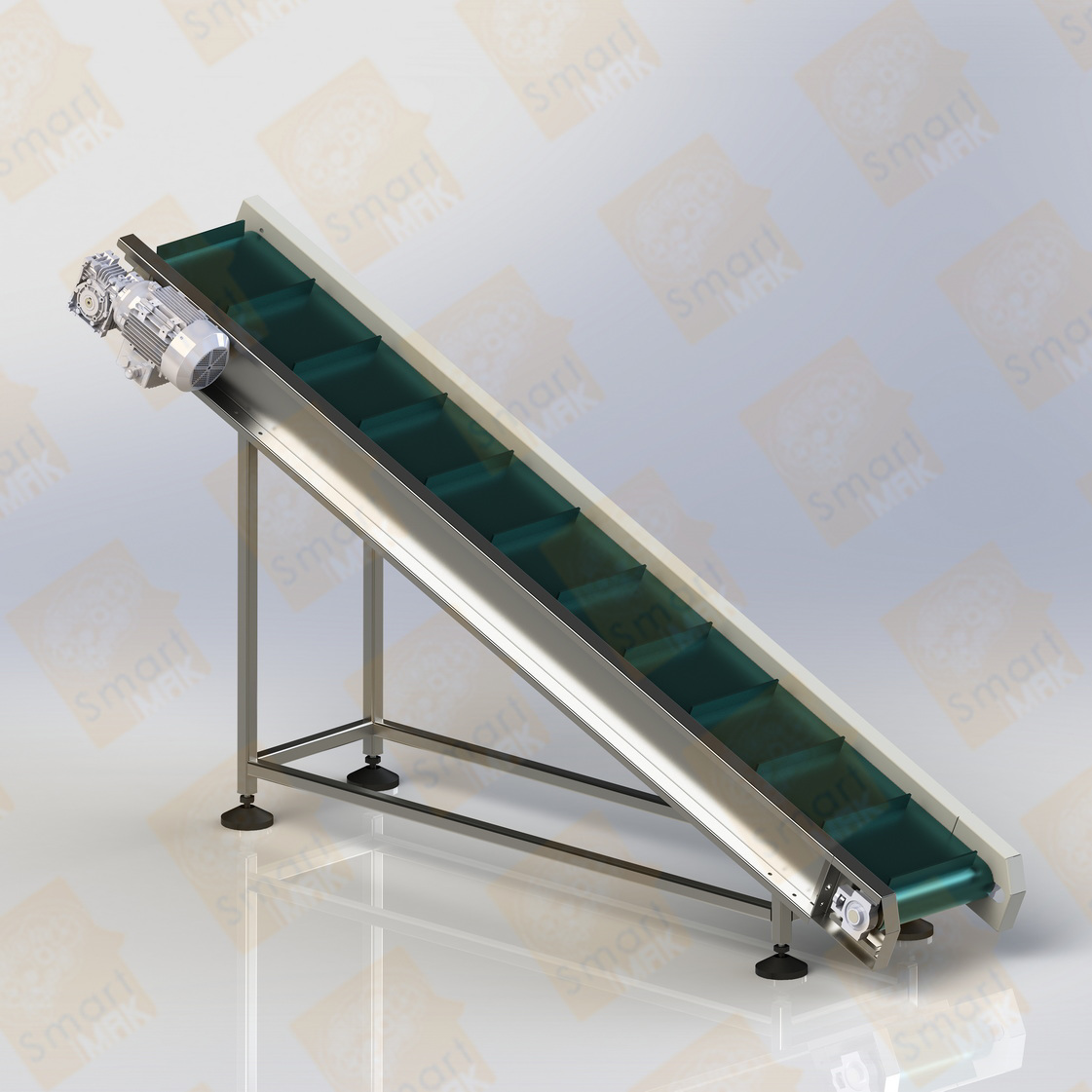

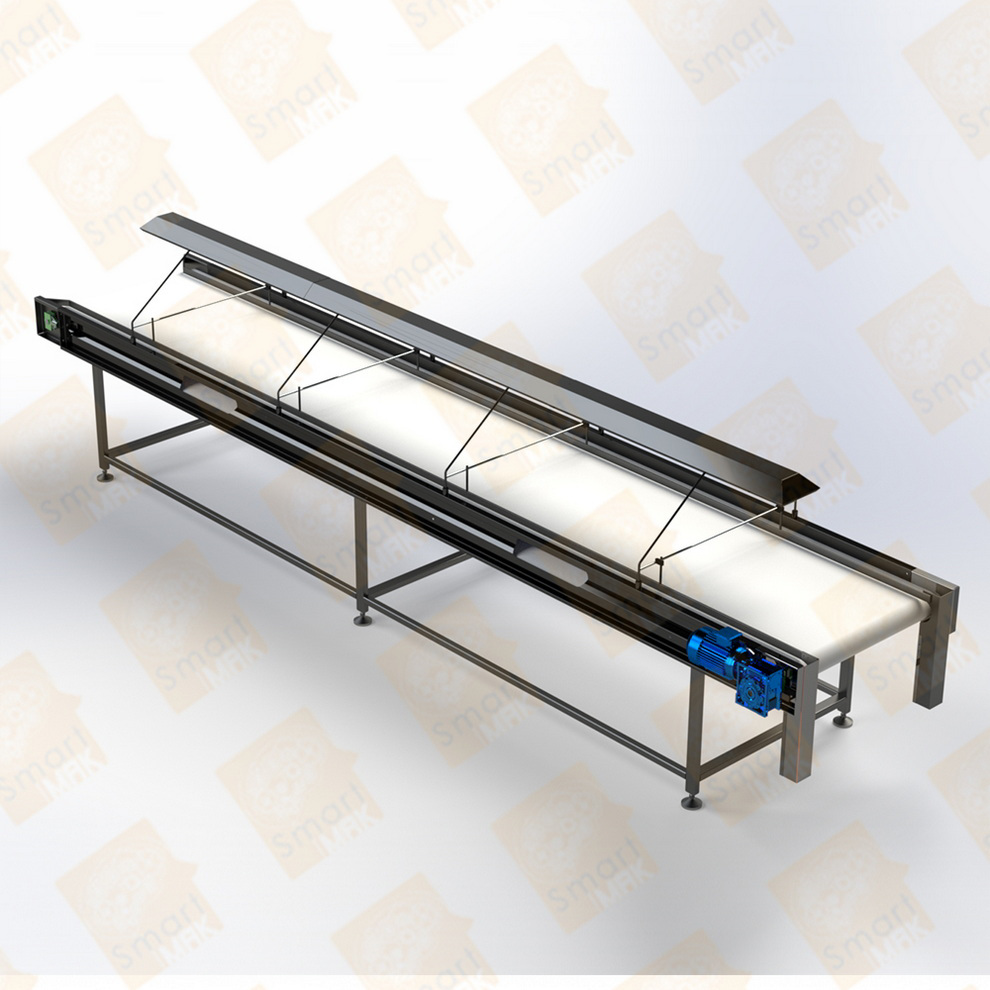

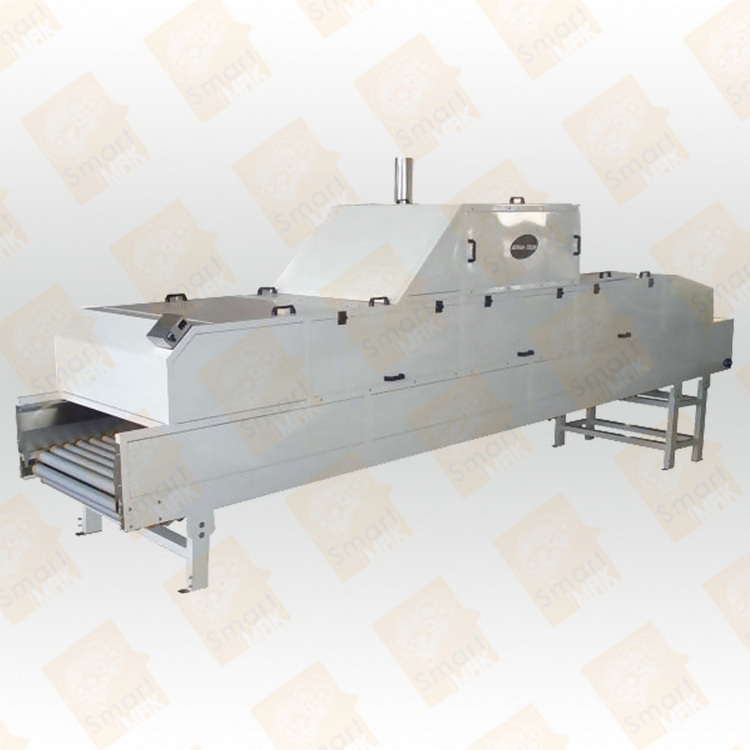

The line starts its work from receiving the fruit boxes through a conveyor belt that takes them to the production line, where a manual sorting process is performed for the fruits to get rid of any fruits that have defects, then the fruits are transferred to the cleaning and drying unit to be subjected there to a washing process using soap and water and then with water only, then the washed fruits pass through the sponge drying section, which dries them, then the fruits pass through the drying tunnel to ensure they are dried and ready for the waxing proccess, then they pass through the waxing unit, which sprays the wax consisting of natural waxy oils on the fruits and distributes it over the entire surface of the fruit, them they pass through a heating tunnel to ensure that the wax is distributed homogeneously on the surface of the fruits, after that the waxed fruits pass on another run for manual sorting to exclude any invalid fruits.

Then the fruits pass through the grading unit, which sorts the fruits according to their size into 12 different sizes according to the diameter of the fruit, then the fruits pass through the packaging process, which workers spread on both sides and fill the fruits in the carton boxes or wooden or plastic crates, which are supplied to them continuously through an automatic moving system (cable car), after which the filled boxes are transferred through the conveyor of the final product to become ready for export or storage.