Dates cleaning and polishing line

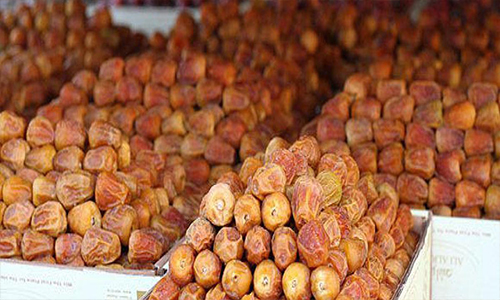

Many selling shops and specialized factories want to sell various foodstuffs, including dates or the like, so these stores are keen to clean and polish the dates before packaging and selling, in order to rid them of the sticks and impurities that are present in them, and this is what makes the dates cleaning and polishing line one of the useful lines and effective for these different factories; Therefore, in our article, we will learn about this line, what it consists of, and what is the principle and mechanism of its work, so that the dates are polished and prepared for packing and selling to the consumer completely.

Dates cleaning and polishing line

The dates cleaning and polishing line is an effective and highly desirable solution for shops that specialize in selling various foodstuffs such as dates, vegetables, mangoes, citrus fruits, avocados, and many others.

The machine is coded SM-215|SM-220 and operates through an automatic packaging system, with a production capacity ranging from 500 to 1500 kilograms per hour. This line works on purifying and cleaning dates or the like from impurities and sticks in them, in order to be ready for packing and packaging in order to sell them to customers and consumers.

It is worth noting that this line contains a special unit for polishing dates in order to give the dates an attractive shine after cleaning them and isolating impurities from them, and then they come out ready for packing without any distorted changes in their shape.

In addition, many companies provide effective services in the manufacture of such lines that are needed by factories and major food stores, and we will learn about the most important sections of this line, how it works and what its most important technical specifications are.

Dates cleaning and polishing line work plan

There is no doubt that the line for cleaning and polishing dates consists of several basic units that are responsible for performing the task of the line by cleaning and polishing dates and giving them an attractive shape that motivates consumers to buy. The way this line works is considered one of the simplest and most accessible ways.

As the units in it perform their functions by integrating with each other to give the desired final result. This cleaning line operates with a high production capacity of about 1.5 tons per hour. Here is how the date cleaning and packing line works, using the following units:

- First, fresh dates are introduced.

- The dates are emptied into the line feed belt, which is the first unit in the line.

- The conveyor feeding the line transfers the dates from it to the next unit, which is the vibrator for sifting dates from sticks and impurities, and thus the task of this vibrator is to isolate the impurities and sticks present from the dates.

- The dates are then transferred to the polishing unit, which consists of a belt equipped with special brushes whose task is to polish the dates to give them an attractive shine without causing damage to them.

- After that, the dates come out clean and polished, ready for packing and selling.

Technical specifications for the date cleaning and polishing line

The technical specifications of the production lines are what most determine the level of their performance in order to accomplish the required work, and despite the diversity and multiplicity of food production and processing lines, customers need reliable companies that manufacture a production line with sufficient technical specifications so that the foodstuffs are fresh and not distorted in shape or composition.

On the other hand, the date cleaning and polishing line is not considered one of the complex lines in the installation, so most of these lines have unified technical specifications and often they all share similar and largely similar specifications, so here are the most important of these technical specifications according to which the line works:

- The structure of the dates cleaning and polishing line is made of food grade stainless steel (L304).

- The line operates at a frequency ranging from 50 to 60 Hz (voltage 380 volts).

- 95% of the mechanical parts of the line are made of food grade stainless steel (L304), while only the motors and some other mechanical parts are made of steel, copper, and aluminium.

- Bacillus: of a kind. SKF.

- Engines and gearboxes are of Turkish manufacture with German distinction.

SmartMAK Company for manufacturing production lines

SmartMAK has established itself as one of the best companies specialized in manufacturing industrial processing lines for many different products, such as some types of sweets, vegetables, fruits, dates, and others.

SmartMAK supports industrial customers such as factories and food stores by providing a wide variety of equipment needed for production lines with high performance, quality, and reliability.

Among the most prominent production lines that it manufactures is the date cleaning and polishing line, which has a major role in purifying dates and preparing them for packaging and then selling in the best way, by designing this line with excellent technical specifications that help its constituent units in isolating impurities and sticks from dates and polishing dates to gain an attractive shine.

With more than 20 years of experience, SmartMAK has been able to leave a mark in the field of manufacturing production lines of all kinds to provide support to customers from all over the world for the continuous preparation of their products.

Thus, we have come to the conclusion of our article, in which we got acquainted with the line for cleaning and polishing dates and the importance of this line for purifying dates from impurities in preparation for selling and exporting them to food stores without changes in their shape, and we note that this line is one of the most simple production lines because its mechanism is done through Simple work units in an organized manner without complication