Chocolate Enrobing Line:

Chocolate Enrobing Line from SmartMak is a practical and suitable solution for obtaining various chocolate dipped products. These products include dates, biscuits and various types of fruits such as strawberries in addition to pastries.

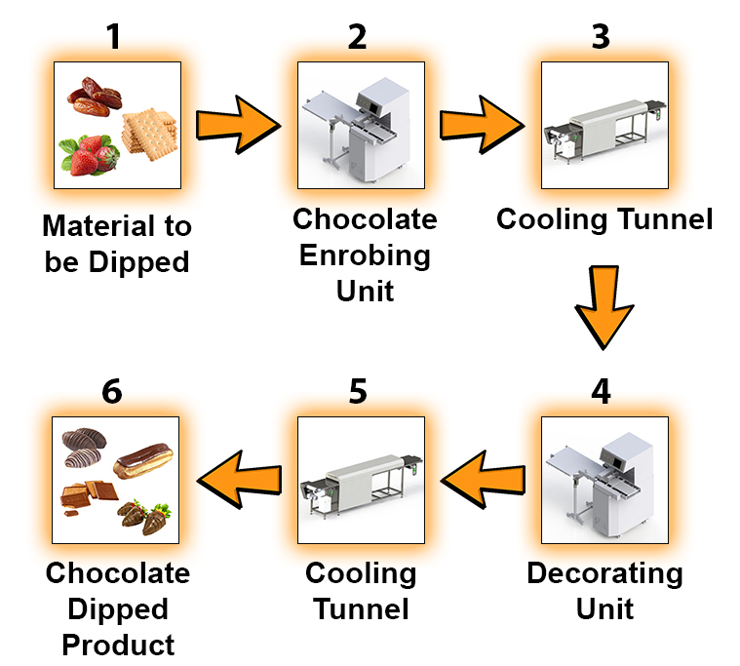

Flowchart - Chocolate Enrobing Line

The work begins by feeding the enrobing unit with the products to be dipped, where the unit adds an upper or lower layer of chocolate, with the ability to control the thickness of the chocolate layer.

The machine includes a system to remove dust through a special fan that directs an air stream to the product to ensure a clean base before starting to dip them.

The unit is attached to a double-jacket tank to feed it with chocolate, whose temperature is maintained and homogenized continuously within the tank through a pump and stirring blades.

The enrobing unit can be supplied with conveyor of different sizes on demand

(250 mm - 400 mm - 600 mm - 800 mm - 1000 mm).

After dipping, the products pass through the cooling tunnel, which ensures that the chocolate is cooled homogeneously, then the dipped pieces proceed to the decorating unit, which decorates the pieces with chocolate according to the required patterns.