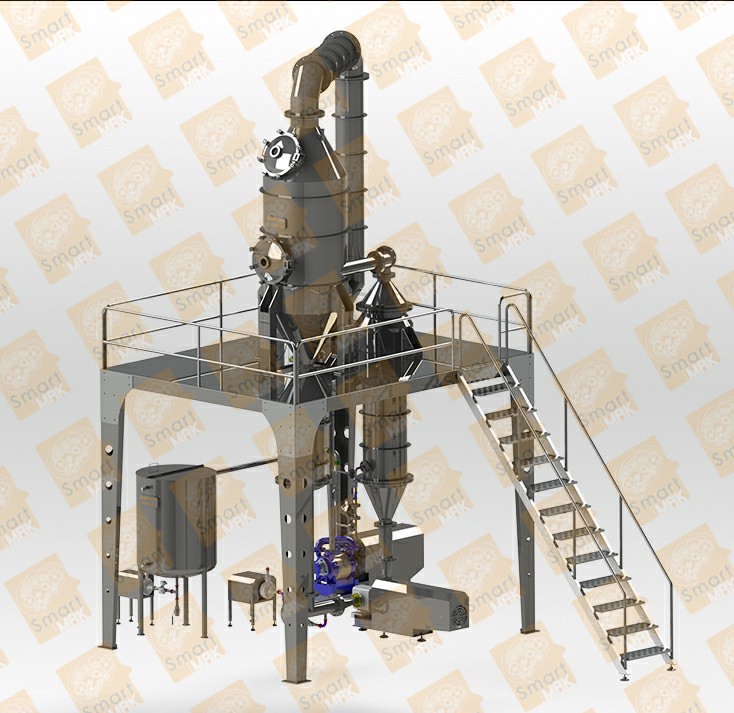

Fruit Jam Processing and Packing Line

The Fruit Jam Production and Filling Line from SmartMak™ offers a distinguished and efficient solution for producing various types of jam. The line offers high-quality jam with an large production capacity of 5 tons per hour.

Complementing the line is a dedicated tank for storing the chosen sweetener, which may consist of Glucose solution, fructose solution, or any other sweetening solution. Additionally, a heating unit is integrated with the tank to reduce the viscosity of the solution, facilitating its seamless pumping through a specialized pump to the production line.

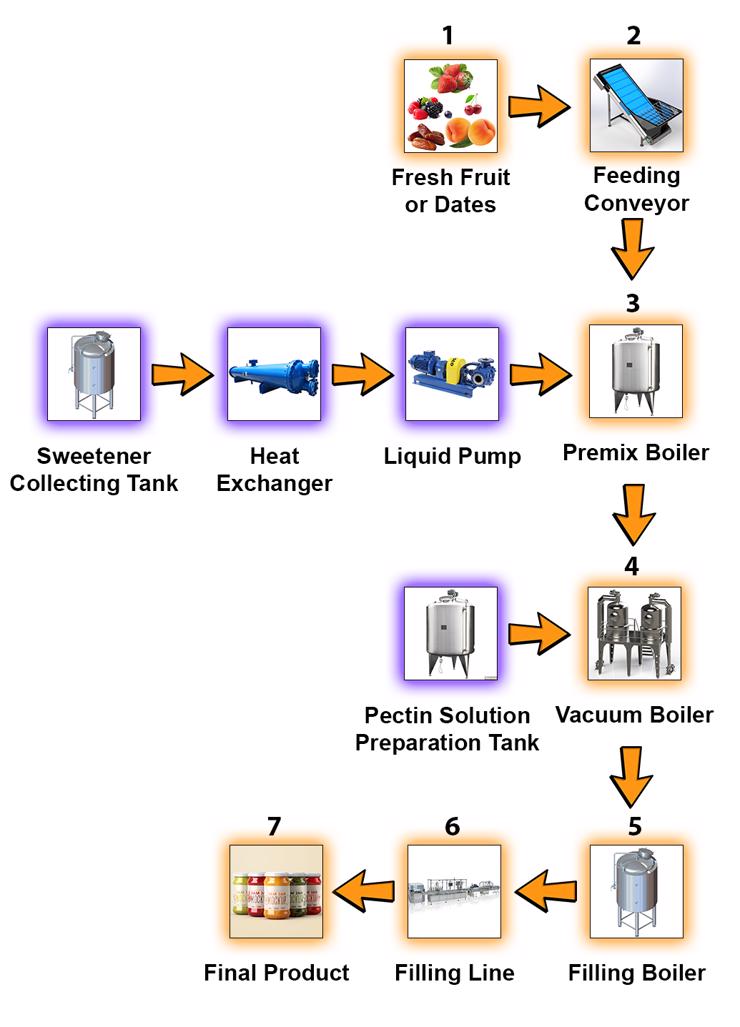

Flowchart - Fruit Jam Processing and Packing Line

The production process begins with fresh and prepared fruits, conveyed through a conveyor to the premix boiler. This boiler, featuring a double jacket tank, heats the fruit and blends it with the sweetener sourced from the storage tank. The resulting mixture is then pumped to the vacuum boiler.

In the vacuum boiler, the mixture undergoes low-pressure cooking. The prepared jam is subsequently transferred to a collection tank, equipped with a mixer and a double jacket, ensuring uniformity and maintaining an optimal temperature for filling.

This tank is seamlessly connected to the filling line, allowing for the packaging of jam in glass or plastic jars according to preferences.