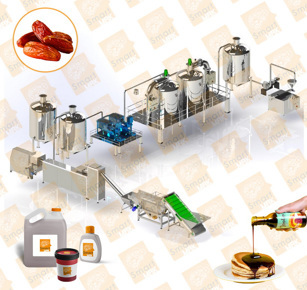

Dates molasses production and packaging line

Date molasses production and packaging lines are considered one of the most important industrial processing lines for various food products and materials such as vegetables, fruits, sweets, and dates. These production lines require a wide range of equipment, and many companies are distinguished by manufacturing these lines to produce these foodstuffs in a pure form and with appropriate and controlled concentrations; Therefore, in this article, we will learn about the dates molasses production and packaging lines, the materials these lines work on, and the technical specifications of the production lines.

Date molasses production and packaging lines

The date molasses production and packaging line is a group of integrated machines used to manufacture date molasses through manual and automatic sequential work stages by a programmed digital control unit, whose function is to adapt the work units to good conditions. In these lines, high-quality stainless steel is used to manufacture most parts of the line, except for some other parts, which include plastics and processed iron, and require multiple production capacities and an effective filtration system.

The date molasses production and packaging line produces raw date molasses with a controlled concentration. But how do these lines work? This production and packaging line starts with dates and ends with packing them into packages of different shapes and sizes, made of plastic, glass or metal. The line is characterized by the presence of a self-washing unit. This unit washes the line completely with chlorine and hot water to sterilize and clean all parts of the line and pipes from the inside.

Date molasses production and packaging lines contribute to a high productivity of up to 500 kg/hour during the day. The production and packaging of date molasses is also done automatically without any manual intervention.

Date molasses production and packaging line mechanism

Date molasses production and packaging lines start from pure dates. But how are the stages of the production and packaging process according to the work of the line? The line work goes through several stages to reach the final stage and complete the work successfully, as the following takes place:

- The dates are transferred to the sugar extraction unit, where water is added to the dates automatically and then the line is continuously in order to extract the largest possible amount of sugars from the date grains.

- All the liquid produced from the sugar extraction process is pumped to a middle collection tank where this liquid is filtered by a piston filter that purifies the liquid from sediment and cores.

- The pure water resulting from the filtration is transferred to a collection tank to condense it into the vacuum condensation tanks, which condense the liquid at low temperatures and relatively low pressure, which works to preserve the properties of the resulting molasses.

- The resulting molasses is conveyed to collection tanks for bottling.

And so, we have mentioned the stages of date molasses production through the dedicated lines. The line is provided with all the necessary equipment to fill the required packages and carton them according to the need and demand for their complete readiness for shipment as a final product, such as providing the line with a plastic gallon filling machine with a capacity of 10 to 25 kg, also it may be provided with a line for filling small metal, plastic or glass containers with a capacity ranging from 100 ml to 1 litre.

What are the specifications of the date molasses filling and production line?

The date molasses production and packaging lines carry out the production and packaging of date molasses by supporting the line with filling machines of different types, as we mentioned, and each production and filling line is characterized by general specifications that work according to it, which are:

- The line produces date molasses with a concentration of 78 Brix, starting with pure dates and ending with filling the resulting date molasses in different packages according to demand.

- The production and packaging line production capacity is between 100 to 500 kg per hour.

- The motors are made of 95% food grade stainless steel while the other mechanical parts are made of steel, copper, and aluminium.

- The production and packaging lines have Omron touch screens that control all machine operations and operate in four different languages.

- Festo pneumatic control systems, gearboxes and controllers are made in Turkey.

- The materials that the machine works on are date paste, date molasses, date syrup, date jam, and date vinegar.

- As for the line accessories in all engines manufactured by the Turkish company Yilmaz, and the electrical parts from the French Schneider company.

SmartMAK is one of the most important companies manufacturing date molasses production and packaging lines.

Smart Mac has a prominent role in manufacturing industrial processing lines for various products such as dates, sweets, vegetables, and fruits. The processing includes packaging and production processes at all stages. The company secures many equipment required and necessary for high-performance and reliable production lines, so that the company guarantees comprehensive support to its industrial customers.