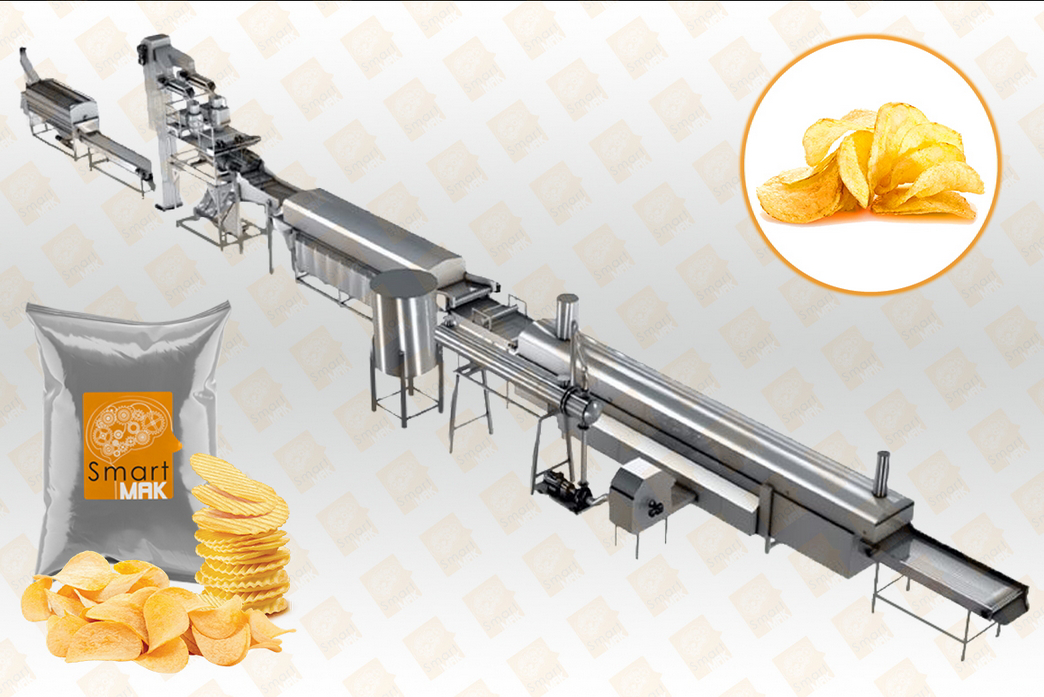

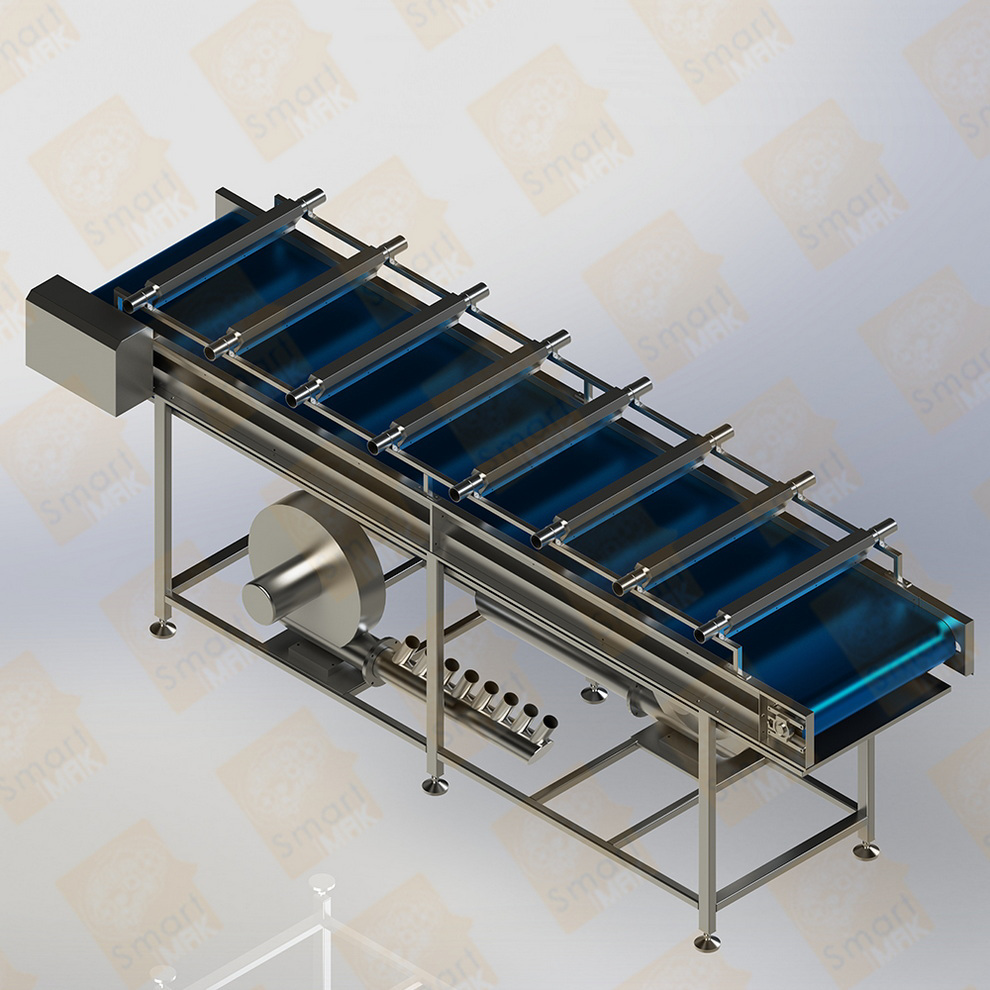

Natural Potato Chips Processing and Packing Line:

The Natural Potato Chips Processing and Packing Line from SmartMak™, is distinguished by its exceptional quality and high production capacity. It operates entirely automatically, eliminating the need for manual intervention, and it adheres to international specifications, holding a CE certification to validate its compliance with quality standards.

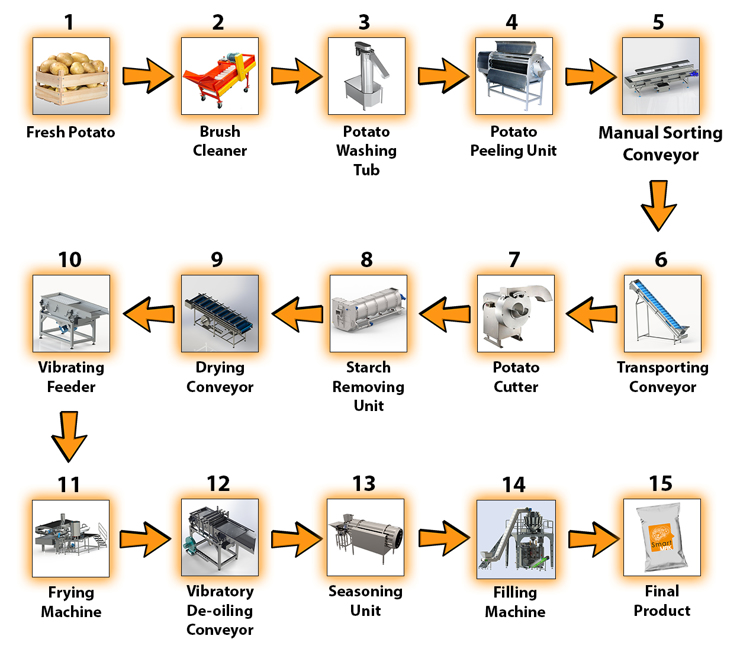

Flow Chart - Natural Potato Chips Processing and Filling Line

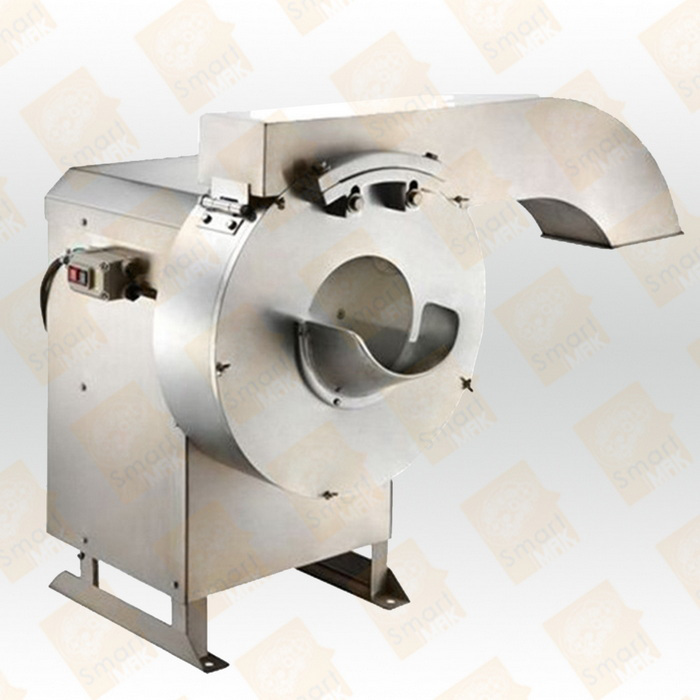

The process begins with the reception of potatoes and progresses to the cleaning stage, where they are purified from dust and peeled using a peeling machine. The potatoes are then sliced into adjustable thicknesses, as desired, including the option to cut them in a flat or zigzag shape.

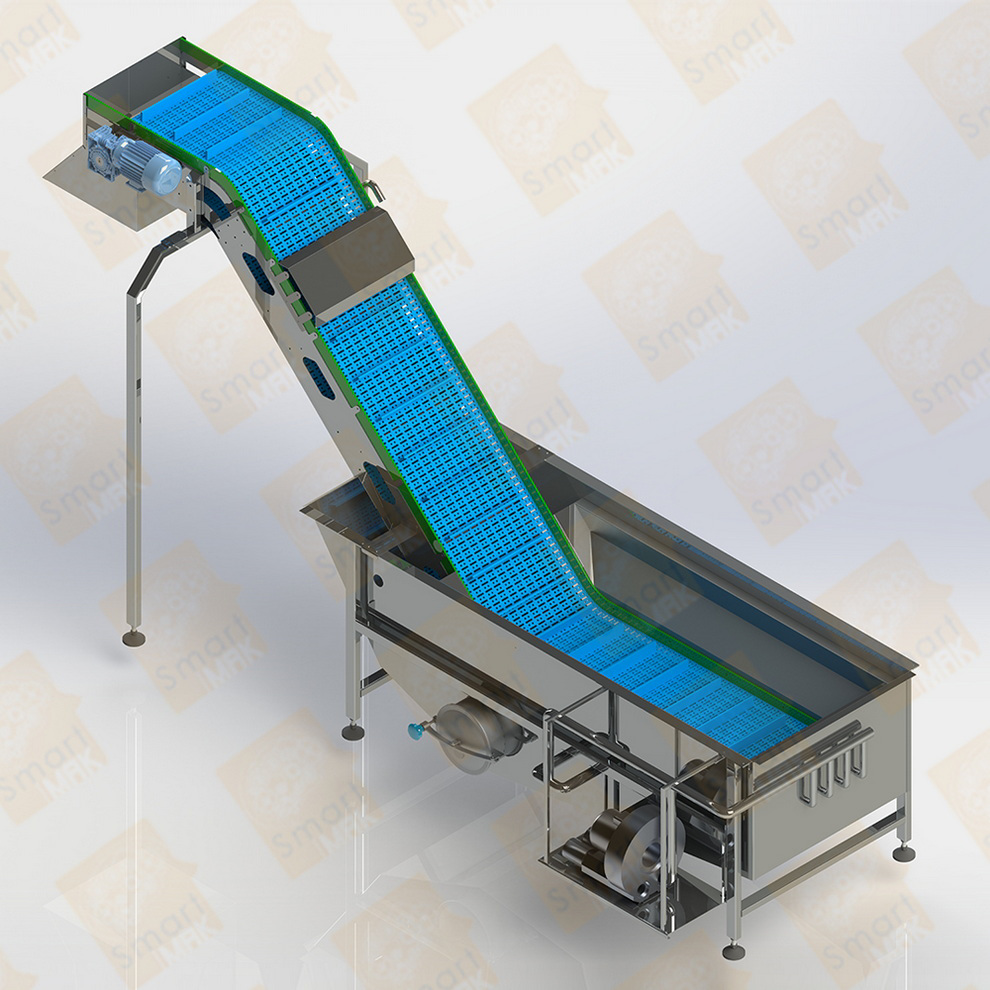

Next, the slices are conveyed to the starch removal unit (Blancher), which ensures the removal of the largest possible amount of starch before frying. This step is vital for several reasons: it contributes to producing crispier chips, reduces contamination of frying oil with potato starch, and many other health-related reasons.

Following starch removal, the slices are processed through a water-drying conveyor system, preparing them for the frying stage. The frying process occurs within a high-efficiency unit, equipped with oil filtration and continuous replenishment mechanisms to maintain oil quality and quantity. The chips are then packaged in bags for the final product.