Dates Washing and Packing Line

The Dates Washing and Cleaning Line from SmartMak™ is characterized by a very high productive capacity of up to 3.5 tons per day, thanks to the seamless coordination between the mechanical operations within the line.

The line ensures the production of sterile dates, perfectly suited for various subsequent operations, be it packaging or direct sales. Notably, this line can also be employed for cleaning a variety of other materials, including citrus and vegetables.

The line has been designed to work continuously without stopping while maintaining precision, and is characterized by ease of cleaning and maintenance.

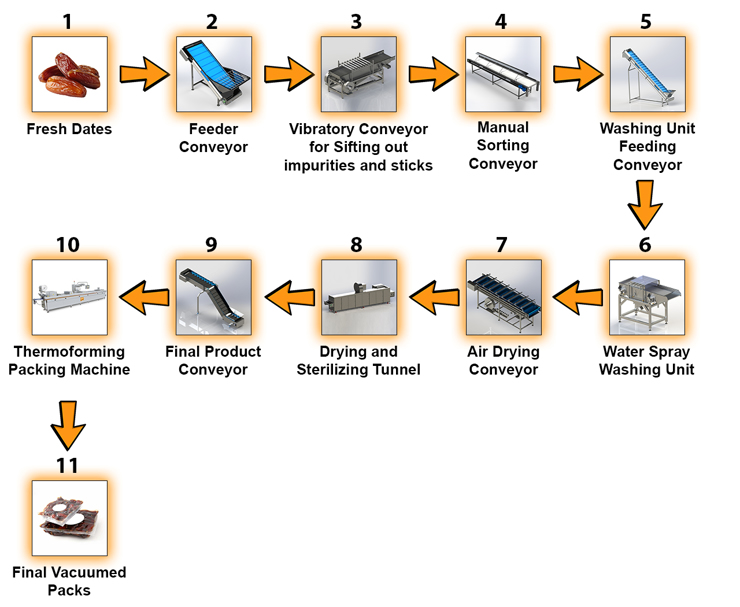

Flowchart - Date Washing and Packing Line

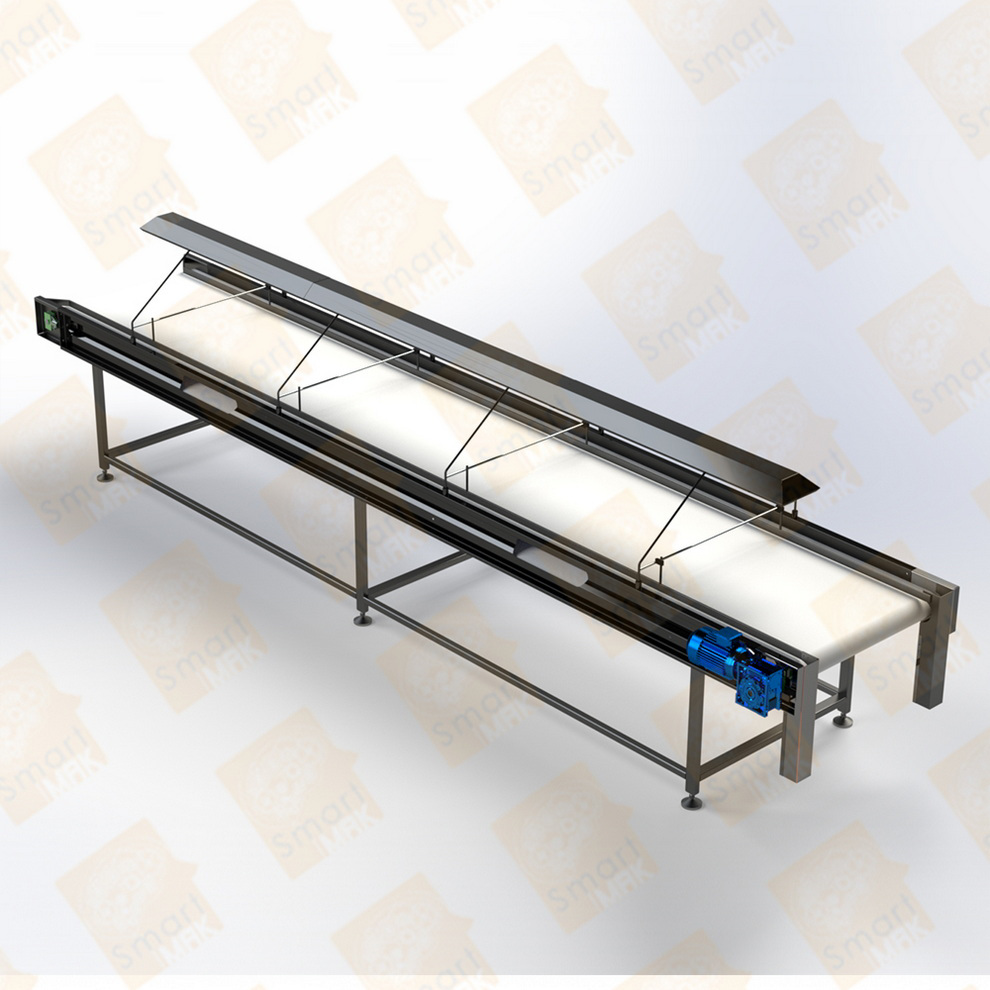

The process begins with dates of varying types and sizes, which are fed into the line via a conveyor belt. This conveyor then transfers the dates to a specially designed vibrator, effectively removing any impurities and sticks that may be among the dates. Subsequently, the dates progress through a quality control and manual sorting conveyor, equipped with overhead lights to facilitate the exclusion of any dates that do not meet the required standards. Workers stationed on both sides of the line are responsible for this process.

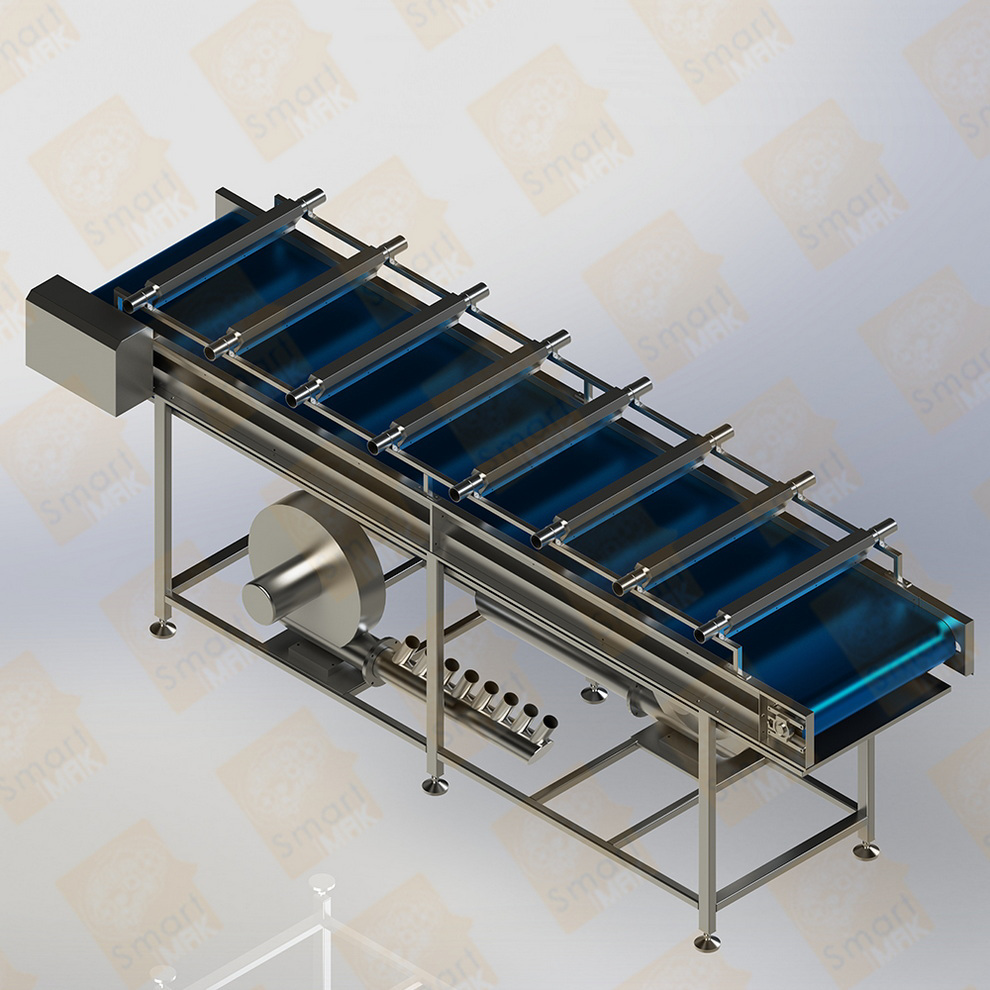

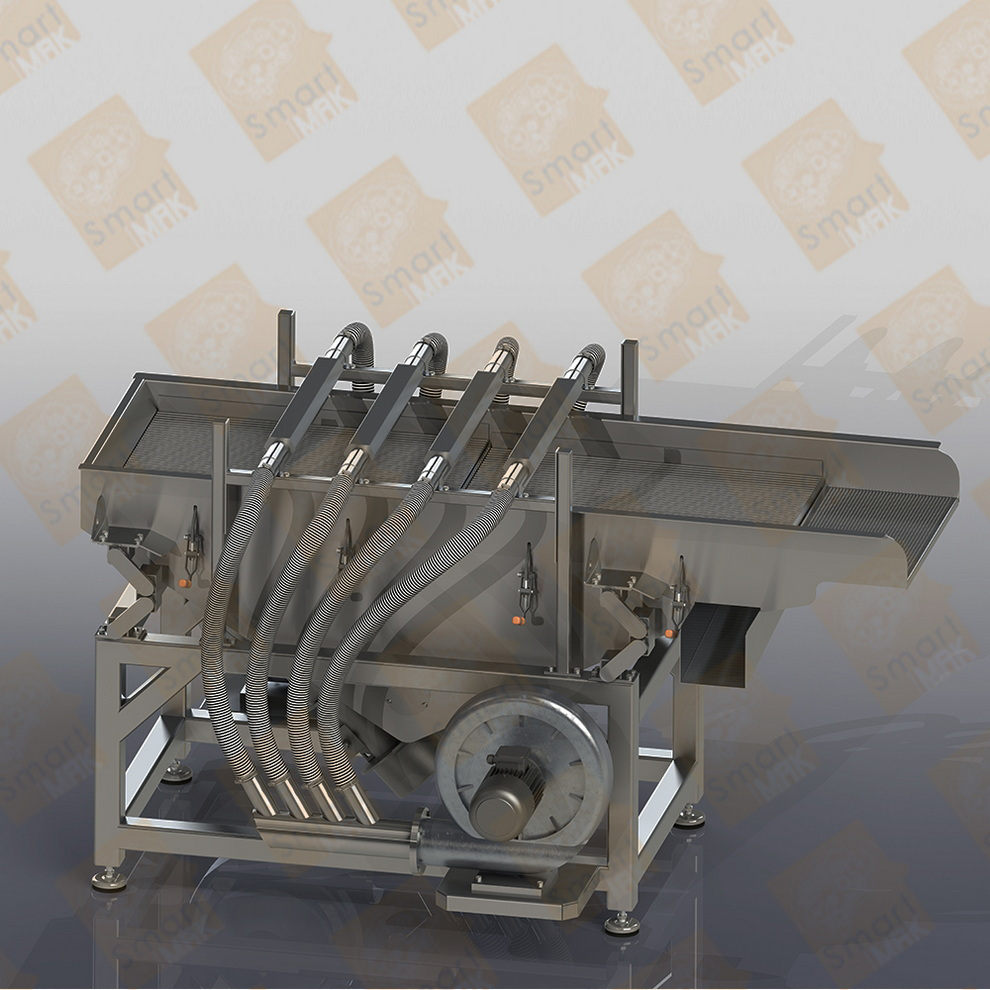

Following this, the dates are conveyed through another conveyor belt to the water spray washing unit, where cold or hot water is sprayed over the dates while continuously vibrating to ensure thorough washing from all angles. Afterward, the washed dates undergo an air-drying process to remove residual washing water, preparing them for the next stage.

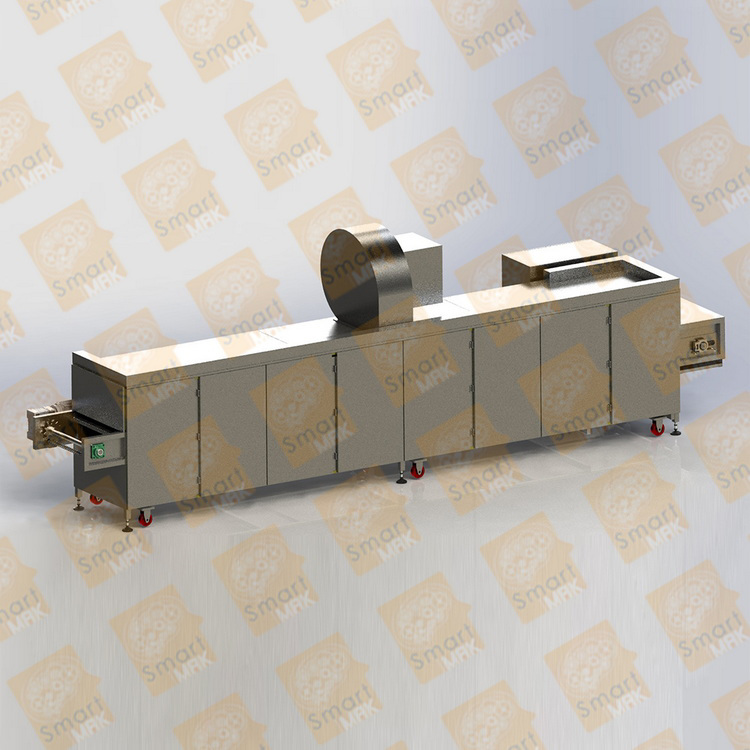

The dates then proceed to a drying and sterilization tunnel, where they are thoroughly dried and sterilized. This process also softens the dates, making them ready for filling if desired.

Finally, the clean and sterilized dates are transported to the final product conveyor, providing us with the end product.