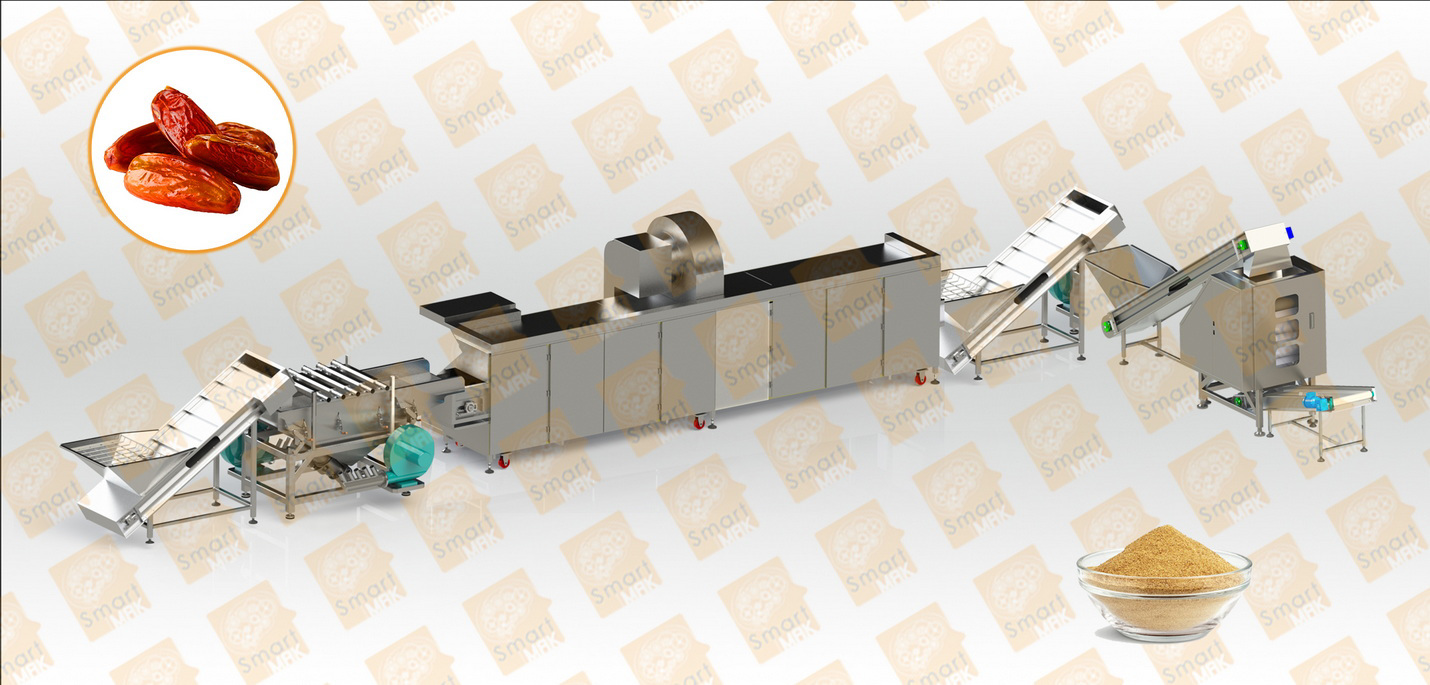

Dates Powder Processing and Packing Line

The Dates Powder Production and Packing Line from SmartMak™ is a practical and suitable solution for obtaining date powder from fresh dates, in addition to the possibility to equip the line with a powder packing machine in plastic containers or sealed bags.

The line is designed to operate continuously without stopping, and is characterized by the harmony of mechanical operations within it, to ensure that no errors or any stoppages occur.

Dates Powder Uses:

The date powder is used as a healthy and safe alternative of table sugar (sucrose) in addition to its use in many desserts, and the containment of the date fruit on vitamins and minerals makes the powder of that fruit a rich source of these nutrients.

The Dates Powder Production and Packing Line from SmartMak™ offers a practical and effective solution for producing date powder from fresh dates. Additionally, the line provides the option to integrate a powder packing machine for packaging in plastic containers or sealed bags.

Designed for continuous operation without interruptions, the line showcases a seamless integration of mechanical operations, ensuring minimal errors and stoppages.

Uses of Dates Powder:

Date powder serves as a healthy alternative to table sugar (sucrose), and may be used in various desserts. Additionally, dates are a great source of vitamins and minerals, making its powder a valuable source of essential nutrients.

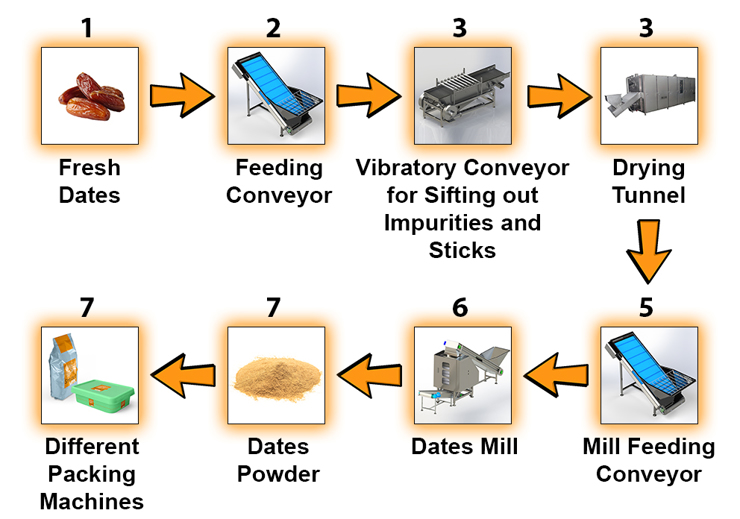

Flow Chart - Dates Powder Processing and Packing Line

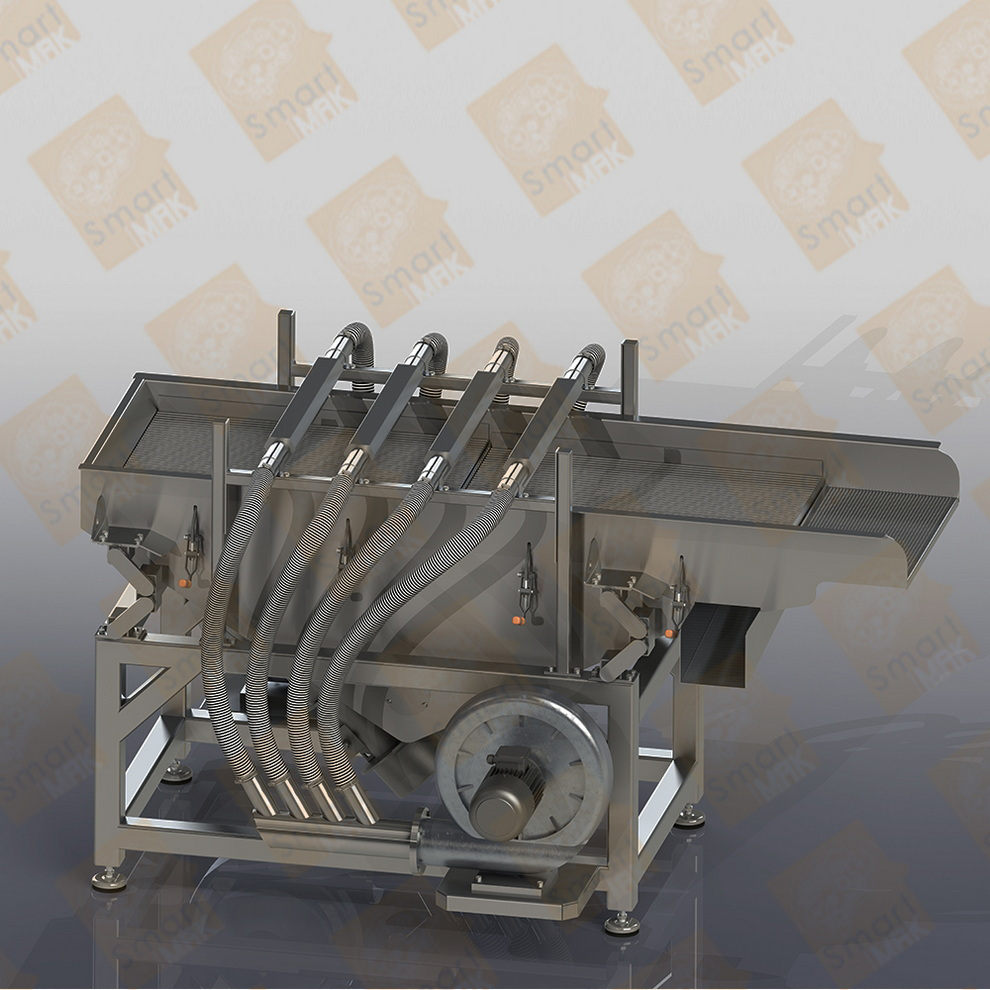

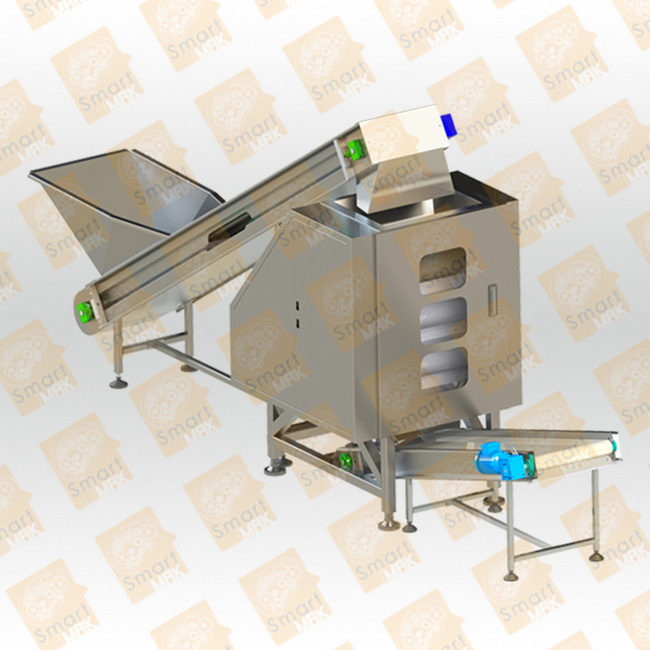

The process begins with various types and sizes of fresh dates, transported to the production line through a feeding conveyor. Initially, the dates pass through the sticks and impurities purification unit, where they are exposed to an air stream and vibration to eliminate any impurities. Subsequently, the dates move to the drying tunnel, where a hot air stream within the oven ensures the grains are thoroughly dried and prepared for grinding.

The dried dates are then transferred via a conveyor belt to the mill, which finely grinds them into powder, ready for use. If the line is equipped with a filling machine, the resulting powder is conveyed through a dedicated conveyor to the filling machine. The filling machine then packages the powder into plastic bags or containers according to the specified weight requirements.